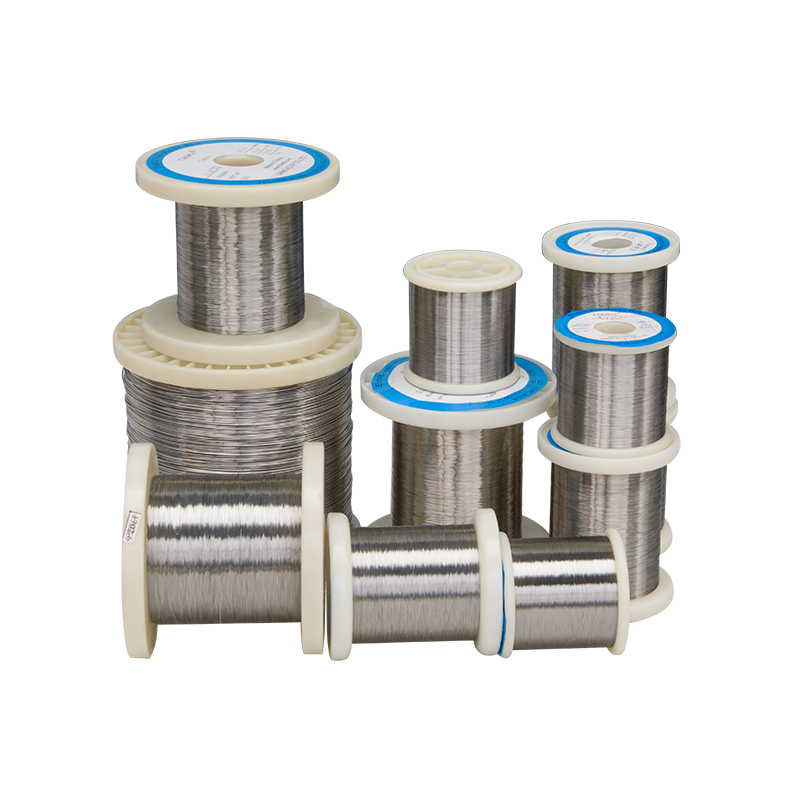

Alloy Mgbasawanye Ala Kovar 4j29 Waya, Waya 29HK maka Alloy Akara Glass

Alloy-4J29 ọ bụghị naanị na ọ nwere mgbasawanye ọkụ dị ka iko, mana enwere ike ịme ka mgbatị ya na-eme ka ọ bụrụ ihe na-eme ka ọ kwekọọ na iko, si otú a na-ekwe ka nkwonkwo na-anabata okpomọkụ dị ukwuu.Kemịkalụ, ọ na-ejikọta na iko site na oyi akwa oxide etiti nke nickel oxide na cobalt oxide;Ọnụ ọgụgụ nke iron oxide dị ala n'ihi mbelata ya na cobalt.Ike nkekọ na-adabere nke ukwuu na ọkpụrụkpụ oyi akwa oxide na agwa.Ọnụnọ nke cobalt na-eme ka oyi akwa oxide dị mfe ịgbaze na igbari na iko a wụrụ awụ.Agba isi awọ, isi awọ-acha anụnụ anụnụ ma ọ bụ isi awọ-agba aja aja na-egosi akara dị mma.Ụcha ọla na-egosi enweghị oxide, ebe ụcha ojii na-egosi metal oxidized gabigara ókè, n'ọnọdụ abụọ a na-eduga na nkwonkwo adịghị ike.

Ngwa:A na-ejikarị ya na ihe ndị na-ekpo ọkụ eletrik na njikwa ikuku, tube ujo, tube ọkụ, magnetron iko, transistor, nkwụnye akara, relay, eriri sekit jikọtara, chassis, brackets na mkpuchi ụlọ ndị ọzọ.

Ngwakọta nkịtị%

| Ni | 28.5-29.5 | Fe | Bal. | Co | 16.8-17.8 | Si | ≤0.3 |

| Mo | ≤0.2 | Cu | ≤0.2 | Cr | ≤0.2 | Mn | ≤0.5 |

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Ike Tensile, MPa

| Koodu ọnọdụ | Ọnọdụ | Waya | Mwepu |

| R | Dị nro | ≤585 | ≤570 |

| 1/4I | 1/4 siri ike | 585-725 | 520-630 |

| 1/2 I | 1/2 siri ike | 655-795 | 590-700 |

| 3/4I | 3/4 siri ike | 725-860 | 600-770 |

| I | siri ike | ≥850 | ≥700 |

Njirimara anụ ahụ ahụkarị

| Njupụta (g/cm3) | 8.2 |

| Igwe ọkụ eletrik na 20ºC (Ωmm2/m) | 0.48 |

| Ọnọdụ okpomọkụ nke resistivity (20ºC ~ 100ºC) X10-5/ºC | 3.7-3.9 |

| Ebe Curie Tc/ºC | 430 |

| Modulus Elastic, E/Gpa | 138 |

Ọnụọgụ nke mgbasawanye

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20-60 | 7.8 | 20-500 | 6.2 |

| 20-100 | 6.4 | 20-550 | 7.1 |

| 20-200 | 5.9 | 20-600 | 7.8 |

| 20-300 | 5.3 | 20-700 | 9.2 |

| 20-400 | 5.1 | 20-800 | 10.2 |

| 20-450 | 5.3 | 20-900 | 11.4 |

Thermal conductivity

| θ/ºC | 100 | 200 | 300 | 400 | 500 |

| λ/ W/(m*ºC) | 20.6 | 21.5 | 22.7 | 23.7 | 25.4 |

| Usoro ọgwụgwọ okpomọkụ | |

| Annealing maka mgbakasị ahụ | Na-ekpo ọkụ na 470 ~ 540ºC ma jide 1 ~ 2 h.Oyi daa |

| annealing | Na agụụ kpụ ọkụ n'ọnụ ruo 750 ~ 900ºC |

| Jide oge | 14 min ~ 1 h. |

| Ọnụọgụgụ jụrụ oyi | Ọ dịghị ihe karịrị 10ºC/min jụrụ ka 200ºC |