Nabata na webụsaịtị anyị!

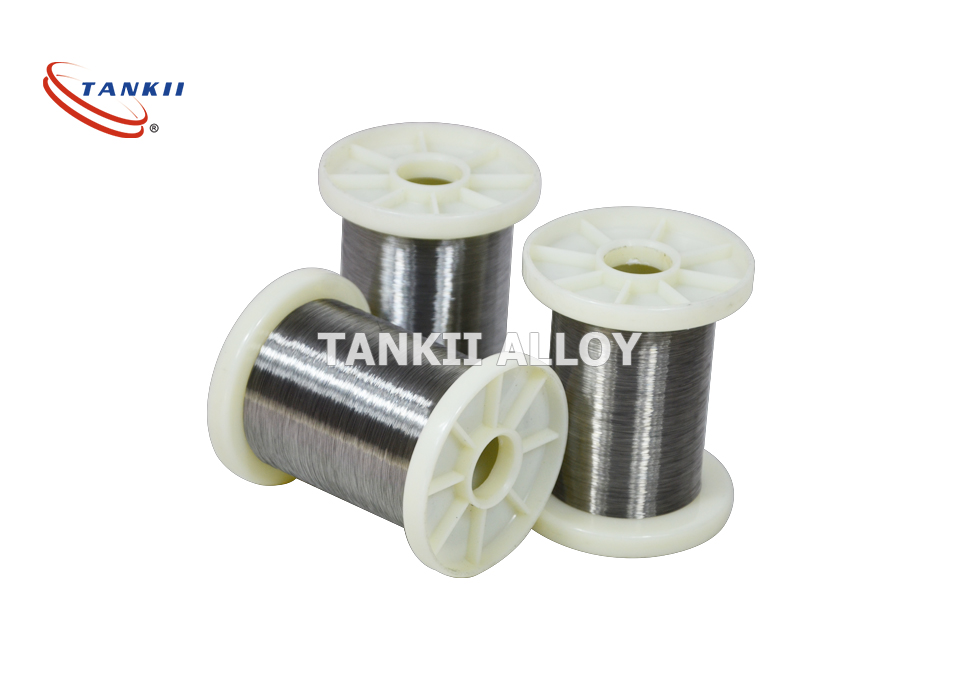

GY FeCrAl 0Cr25Al5 waya na-eguzogide maka ikpo ọkụ tubular

GY FeCrAl OCr25Al5 waya mgbochi makatubular kpo oku

| Aha ngwaahịa | Oke oke |

| Oyi ịbịaru waya | Dayameta 0.03-7.5mm |

| mkpanaka waya na-ekpo ọkụ | Dayameta 8.0-12mm |

| Ribọn | Ọkpụrụkpụ 0.05-0.35mm |

| Obosara 0.5.0-3.5mm | |

| Oyi akpọrepu eriri | Ọkpụrụkpụ 0.5-2.5mm |

| Obosara 5.0-40mm | |

| na-ekpo ọkụ akpọrepu eriri | Ọkpụrụkpụ 4-6 mm |

| Obosara 15-40mm |

Banyere waya kpo oku na-eguzogide:

Anyị bụ ndị ọkachamara kasị ukwuu emeputa nke iguzogide kpo oku alloy na China, ọkachamara na Ferro-Chrome (Fe-Cr-AL) waya, Nickel-Chrome (Nichrome) waya, ọla kọpa nickel (Constantan) waya, igwe anaghị agba nchara waya na yiri ngwaahịa alloys. ahaziri iji mezuo ihe ndị ahịa chọrọ

Nkọwa nha

ntọala ntọala:

| isi parameters | Kanthall APMTM | Kanthall | ||

| A-1 | AF | D | ||

| Ọnọdụ okpomọkụ na-aga n'ihu kachasị elu | 1425 | 1400 | 1300 | 1300 |

| Ngwakọta kemịkalụ ọnụ,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | ihe eji eme ihe | ihe eji eme ihe | ihe eji eme ihe | ihe eji eme ihe |

| Ni | - | - | - | - |

| The resistivity na 20ºC,Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| njupụta,g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| Ọnụọgụ mgbasawanye okpomọkụ K-1 20-750ºC | 14×10-6 | 14×10-6 | 14×10-6 | 14×10-6 |

| 20-1000ºC | 15×10-6 | 15×10-6 | 15×10-6 | 15×10-6 |

| Thermal conductivity 20ºC, Wm-1K-1 | 13 | 13 | 13 | 13 |

| Pụrụ iche okpomọkụ ike 20ºC,KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Ebe mgbazeºC | 1500 | 1500 | 1500 | 1500 |

| Eleghi anya njiri mara | ||||

| Ike ntanye, N mm-2 | 680 | 680 | 680 | 650 |

| Ike nke mkpụrụ, N mm-2 | 470 | 475 | 475 | 450 |

| Isi ike, Hv | 230 | 230 | 230 | 230 |

| Na-agbaji elongation,% | 20 | 18 | 18 | 18 |

| 900ºCT ike ike, N mm-2 | 40 | 34 | 37 | 34 |

| Ike na-akpụ akpụ 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Magnetik | magnetik (na okpomọkụ 600ºC) | |||

| Emissivity, ọnọdụ oxidation | 0.7 | 0.7 | 0.7 | 0.7 |

Nkọwapụta:

| Ụdị Alloy | Dayameta | Nguzogide | Mgbatị | Mgbatị(%) | Na-ehulata | Max.Na-aga n'ihu | Ndụ arụ ọrụ |

| (mm) | (μΩm)(20°C) | Ike | Oge | Ọrụ | (awa) | ||

| (N/mm²) | Okpomọkụ(°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09± 0.05 | 850-950 | >20 | >9 | 1200 | > 20000 |

| 0.50-3.0 | 1.13 ± 0.05 | 850-950 | >20 | >9 | 1200 | > 20000 | |

| > 3.0 | 1.14± 0.05 | 850-950 | >20 | >9 | 1200 | > 20000 | |

| Cr30Ni70 | <0.50 | 1.18± 0.05 | 850-950 | >20 | >9 | 1250 | > 20000 |

| ≥0.50 | 1.20± 0.05 | 850-950 | >20 | >9 | 1250 | > 20000 | |

| Cr15Ni60 | <0.50 | 1.12± 0.05 | 850-950 | >20 | >9 | 1125 | > 20000 |

| ≥0.50 | 1.15± 0.05 | 850-950 | >20 | >9 | 1125 | > 20000 | |

| Cr20Ni35 | <0.50 | 1.04± 0.05 | 850-950 | >20 | >9 | 1100 | > 18000 |

| ≥0.50 | 1.06 ± 0.05 | 850-950 | >20 | >9 | 1100 | > 18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25± 0.08 | 588-735 | >16 | > 6 | 950 | > 10000 |

| 0Cr15Al5 | 1.25± 0.08 | 588-735 | >16 | > 6 | 1000 | > 10000 | |

| 0Cr25Al5 | 1.42± 0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42± 0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23 ± 0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45± 0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53± 0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Uru:

Nickelchromium alloy na elu na kwụsie ike nguzogide, corrosion eguzogide, elu ọxịdashọn nguzogide dị mma, mma n'okpuru elu okpomọkụ na seismic ike, ezi ductility, ezi workability na weldability.

Nickelchromium alloy na elu na kwụsie ike nguzogide, corrosion eguzogide, elu ọxịdashọn nguzogide dị mma, mma n'okpuru elu okpomọkụ na seismic ike, ezi ductility, ezi workability na weldability.

Dee ozi gị ebe a ziga anyị ya