Nabata na webụsaịtị anyị!

FeNi Nickel Ígwè Alloy Precision 0.5mm Invar 36 Waya Maka Akara Ngwa Ngwa nkenke

FeNi Nickel Iron Alloy nkenke 0.5mmInvar 36 Wayamaka Akara nkenke Ngwa

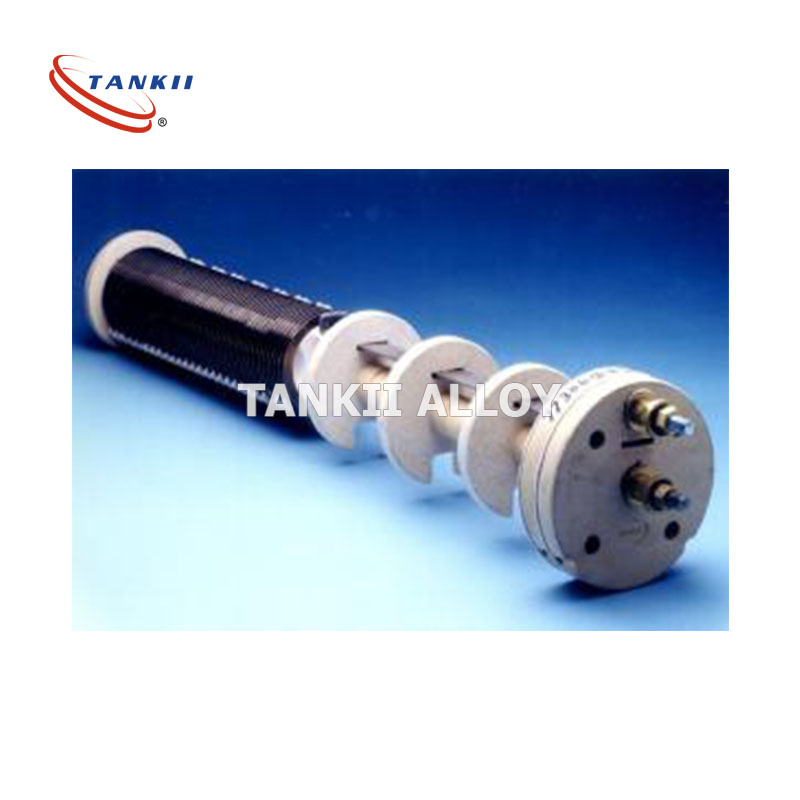

INVAR 36bụ nickel-ígwè, ala mgbasawanye alloy nwere 36% nickel.Ọ na-edobe ihe fọrọ nke nta ka ọ bụrụ mgbe niile N'ime oke ikuku ikuku nkịtị, ma nwee obere ọnụọgụ nke mgbasawanye site na okpomọkụ cryogenic ruo ihe dịka 500 ° F. Alloy na-ejigide ike na ike siri ike na okpomọkụ cryogenic.

INVAR 36nwere ike na-ekpo ọkụ na oyi kpụrụ na machined iji usoro yiri

austenitic igwe anaghị agba nchara.INVAR 36 nwere ike weldable site na iji Filler Metal CF36 nke bụ

dị na waya efu maka ma usoro GTAW na GMAW.

Ngwakọta kemịkalụ

| mejupụtara | % | Fe | Ni | Mn | C | P | S | SI |

| ọdịnaya | min | Bal | 35.0 | 0.2 | ||||

| max | 37.0 | 0.6 | 0.05 | 0.02 | 0.02 | 0.3 |

Njirimara anụ ahụ

| Njupụta (g/cm3) 8.1 |

| Igwe ọkụ eletrik na 20ºC (mm2/m) 0.78 |

| Ọnọdụ okpomọkụ nke resistivity (20ºC ~ 200ºC) X10-6/ºC 3.7 ~ 3.9 |

| Nrụpụta ọkụ, λ/W/(m*ºC) 11 |

| Ebe Curie Tc/ºC 230 |

| Elastic Modulus, E/Gpa 144 |

| Ebe mgbaze ºC 1430 |

Ọnụọgụ nke mgbasawanye

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20--60 | 1.8 | 20-250 | 3.6 |

| 20--40 | 1.8 | 20-300 | 5.2 |

| 20--20 | 1.6 | 20-350 | 6.5 |

| 20 ~-0 | 1.6 | 20-400 | 7.8 |

| 20-50 | 1.1 | 20-450 | 8.9 |

| 20-100 | 1.4 | 20-500 | 9.7 |

| 20-150 | 1.9 | 20-550 | 10.4 |

| 20-200 | 2.5 | 20-600 | 11.0 |

Njirimara igwe eji eme ihe

| Ike ọdụdọ | Ogologo oge |

| Mpa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Ọnọdụ okpomọkụ nkeResistivity

| Oke okpomọkụ, ºC | 20-50 | 20-100 | 20-200 | 20-300 | 20-400 |

| AR/ 103 *ºC | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

| Usoro ọgwụgwọ okpomọkụ | |

| Annealing maka mgbakasị ahụ | Na-ekpo ọkụ na 530 ~ 550ºC ma jide 1 ~ 2 h.Oyi daa |

| annealing | Iji kpochapụ hardening, nke a ga-ewepụta na oyi na-atụ, usoro ịbịaru oyi.Annealing kwesịrị ikpo ọkụ na 830 ~ 880ºC na agụụ, jide 30 min. |

| Usoro nkwụsi ike | Na mgbasa ozi nchebe ma kpoo ọkụ ruo 830ºC, jide 20min.~ 1h, emenyụ N'ihi nrụgide sitere na quenching, na-ekpo ọkụ ruo 315ºC, jide 1 ~ 4h. |

| Mkpachapụ anya | Enweghị ike imesi ike site na ọgwụgwọ okpomọkụ Ngwọta dị n'elu nwere ike ịbụ ájá na-agbaze, polishing ma ọ bụ pickling. Enwere ike iji alloy 25% hydrochloric acid pickling solution na 70ºC iji kpochapụ elu oxidized. |

Dee ozi gị ebe a ziga anyị ya