Nnọọ na weebụsaịtị anyị!

Tankii J-Type Thermocouple Bare Waya SWG30/SWG25/SWG19 High Thermous Sensitivity

Nkọwa Ngwaahịa

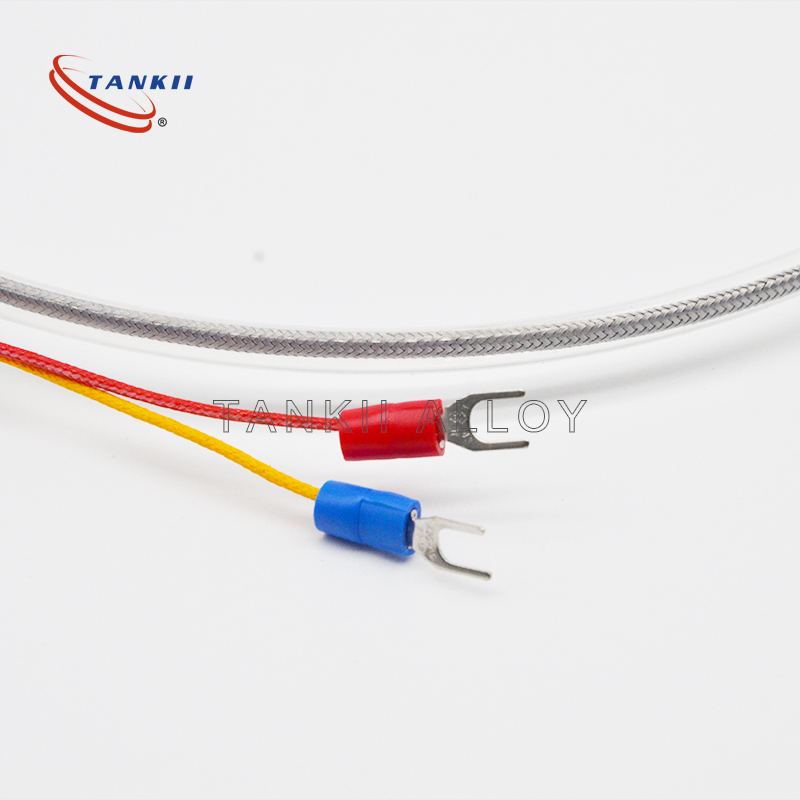

Waya Thermocouple Bare Type J (SWG30/SWG25/SWG19)

Nchịkọta Ngwaahịa

Waya thermocouple nke ụdị J, nke Tankii Alloy Material mepụtara, nwere ihe abụọ na-eduzi alloy dị iche iche—ígwè (ụkwụ dị mma) na constantan (ọla kọpa-nickel alloy, ụkwụ na-adịghị mma)—nke e mepụtara maka nha okpomọkụ ziri ezi na gburugburu okpomọkụ dị mma. Dị na nha waya atọ a na-ahụkarị: SWG30 (0.305mm), SWG25 (0.51mm), na SWG19 (1.02mm), waya a na-ewepụ nnyonye anya mkpuchi, na-eme ka ọ dị mma maka mgbakọ thermocouple omenala, nhazi okpomọkụ dị elu, na ngwa ndị chọrọ kọntaktị ozugbo na mgbasa ozi a tụrụ. Site na iji teknụzụ ịgbaze na ise ihe nke alloy dị elu nke Huona, nha ọ bụla na-ejigide ndidi siri ike na njirimara thermoelectric kwụsiri ike, na-ahụ na ọ na-adịgide adịgide n'ofe otu.

Nhọpụta ọkọlọtọ

- Ụdị Thermocouple: J (Iron-Constantan)

- Ihe nlele waya: SWG30 (0.315mm), SWG25 (0.56mm), SWG19 (1.024mm)

- Ụkpụrụ Mba Nile: Na-agbaso IEC 60584-1, ASTM E230, na GB/T 4990

- Ụdị: Waya gba ọtọ (anaghị ekpuchi ihe mkpuchi, maka mkpuchi/nchekwa omenala)

- Onye Mmepụta: Tankii Alloy Material, nke a kwadoro na ISO 9001 ma kwadoro ya dịka ụkpụrụ okpomọkụ mba si dị.

Uru Ndị Dị Mkpa (vs. Waya J-Type Insulated & Ụdị Thermocouple Ndị Ọzọ)

Ngwọta waya a na-enweghị ihe ọ bụla pụtara ìhè maka ịdị mfe ya, izi ezi ya, na mgbanwe ya kpọmkwem maka nha:

- Arụmọrụ E Ji Gauge Mee: SWG30 (ihe dị gịrịgịrị) na-enye nnukwu mgbanwe maka nrụnye oghere siri ike (dịka ọmụmaatụ, obere ihe mmetụta); SWG19 (ihe dị arọ) na-enye ike mekaniki ka mma maka gburugburu ụlọ ọrụ mmepụta ihe; SWG25 na-edozi mgbanwe na ịdịte aka maka ojiji izugbe.

- Ezigbo Oke Ọkụ: Na-emepụta ike eletriki kwụsiri ike (EMF) nke nwere mmetụta nke ~52 μV/°C (na 200°C), na-arụ ọrụ karịa Ụdị K na oke 0-500°C, yana izi ezi nke Klas 1 (nchekwa: ±1.5°C ma ọ bụ ±0.25% nke ọgụgụ, nke ọ bụla buru ibu).

- Ọdịdị Waya Bare: Enweghị mkpuchi etinyere tupu oge eruo na-enye ndị ọrụ ohere ịhazi nchebe (dịka ọmụmaatụ, tube seramiiki, ihe mkpuchi fiberglass) dabere na ihe achọrọ maka okpomọkụ/njehie, na-ebelata ihe mkpofu sitere na waya ndị a kpọchiri akpọchi na-adabaghị adaba.

- Ọnụ Ego: Aluminom ígwè na-agbanwe agbanwe dị ọnụ ala karịa thermocouples metal dị oke ọnụ ahịa (Ụdị R/S/B) ebe ọ na-enye mmetụta dị elu karịa Ụdị K, nke na-eme ka ọ dị mma maka nha okpomọkụ etiti (0-750°C) na-enweghị mmefu karịrị akarị.

- Ezigbo Nguzogide Oxidation: Ọ na-arụ ọrụ nke ọma n'ebe ikuku na-agbaze ruo 750°C; onye na-eduzi ígwè na-emepụta oyi akwa oxide nchebe nke na-ebelata mbugharị, na-agbatị ndụ ọrụ na waya ígwè na-enweghị alloyed.

Nkọwapụta Nkà na ụzụ

| Njirimara | SWG30 (0.315mm) | SWG25 (0.56mm) | SWG19 (1.024mm) |

|---|---|---|---|

| Ihe Onye Na-eduzi | Nke dị mma: Ígwè; Na-adịghị mma: Constantan (Cu-Ni 40%) | Nke dị mma: Ígwè; Na-adịghị mma: Constantan (Cu-Ni 40%) | Nke dị mma: Ígwè; Na-adịghị mma: Constantan (Cu-Ni 40%) |

| Dayameta aha | 0.305mm | 0.51mm | 1.02mm |

| Nnwale Dayameta | ±0.01mm | ±0.015mm | ±0.02mm |

| Oke okpomọkụ | Na-aga n'ihu: 0-700°C; Oge dị mkpirikpi: 750°C | Na-aga n'ihu: 0-750°C; Oge dị mkpirikpi: 800°C | Na-aga n'ihu: 0-750°C; Oge dị mkpirikpi: 800°C |

| EMF na 100°C (vs 0°C) | 5.268 mV | 5.268 mV | 5.268 mV |

| EMF na 750°C (vs 0°C) | 42.919 mV | 42.919 mV | 42.919 mV |

| Nguzogide Onye Na-eduzi (20°C) | ≤160 Ω/km | ≤50 Ω/km | ≤15 Ω/km |

| Ike nrụgide (20°C) | ≥380 MPa | ≥400 MPa | ≥420 MPa |

| Ogologo (20°C) | ≥20% | ≥22% | ≥25% |

Nkọwapụta Ngwaahịa

| ihe | Nkọwapụta |

|---|---|

| Mmecha Elu | A na-egbuke egbuke (enweghị oxide, Ra ≤0.2μm) |

| Fọm Ntinye | Spools (ogologo: 50m/100m/300m kwa nha) |

| Ọcha Kemịkalụ | Ígwè: ≥99.5%; Constantan: Cu 59-61%, Ni 39-41%, adịghị ọcha ≤0.5% |

| Nhazi | A pụrụ ịchọta ya na NIST/China National Institute of Metrology (CNIM) |

| Nkwakọ ngwaahịa | A na-emechi vaskụla n'ime akpa ejiri argon jupụta (iji gbochie oxidation); ihe mkpuchi plastik n'ime katọn ndị na-anaghị amị mmiri |

| Nhazi | Ogologo ya (opekempe 1m), ịdị ọcha pụrụ iche nke alloy (ígwè dị ọcha maka nhazi), ma ọ bụ nsọtụ e tinyere n'ime ite. |

Ngwa Ndị A Na-ahụkarị

- Mgbakọ Thermocouple Pụrụ Iche: Ndị na-emepụta ihe mmetụta na-eji ya arụpụta ihe nyocha nwere nchedo pụrụ iche maka ngwa (dịka ọmụmaatụ, ihe nyocha seramiiki maka ọkụ, ihe nyocha igwe anaghị agba nchara maka mmiri mmiri).

- Nchọpụta Okpomọkụ Ụlọ Ọrụ: Ntụle kpọmkwem n'ihe gbasara nhazi nri (ime achịcha n'ime oven, 100-300°C) na ịkpụzi plastik (okpomọkụ gbazee, 200-400°C)—a na-ahọrọ SWG25 maka nhazi nke mgbanwe na ike.

- Ngwa Nhazi: Ihe ntụaka dị na ihe nhazi okpomọkụ (SWG30 maka mkpụrụ ndụ nhazi obere).

- Nnwale Ụgbọala: Na-enyocha okpomọkụ nke blọk injin na sistemu iwụpụ (SWG19 maka iguzogide ịma jijiji).

- Nnyocha Ụlọ Nyocha: Nhazi ọkwa okpomọkụ na nnwale sayensị ihe onwunwe (0-700°C) ebe achọrọ mkpuchi pụrụ iche.

Tankii Alloy Material na-enyocha waya ọ bụla nke ụdị J site na nnwale dị mma siri ike: ule nkwụsi ike thermoelectric (usoro 100 nke 0-750°C), nyocha nha (micrometry laser), na nyocha nhazi kemịkalụ (XRF). Enwere ike ịnweta ihe nlele efu (1m kwa nha) na asambodo nhazi mgbe a rịọrọ ya. Ndị otu teknụzụ anyị na-enye nduzi ahaziri ahazi - gụnyere nhọrọ nha maka ngwa akọwapụtara na omume kachasị mma nke ịgbado ọkụ/ịgbado ọkụ - iji hụ na arụmọrụ kacha mma na ntọala thermocouple ahaziri ahazi.

Dee ozi gị ebe a zitere anyị ya

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu