Nnọọ na weebụsaịtị anyị!

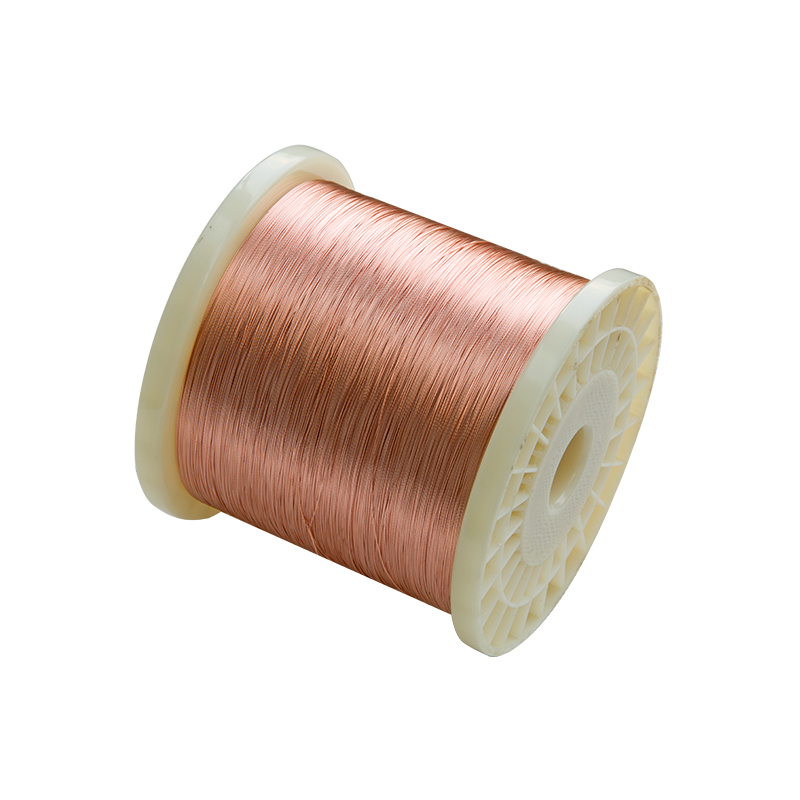

Tankii 1.0mm waya ọla kọpa T2 nke nwere ọla kọpa uhie na-egbochi oxidation na ezigbo conductivity

Nkọwa Ngwaahịa

Waya Kọpa 1.0mm a gbanyere n'ime ite (Isi Kọpa Uhie Dị Ọcha, Mkpuchi Tin 3-5μ)

Nchịkọta Ngwaahịa

Dịka onye na-eduzi eletriki a pụrụ ịtụkwasị obi nke Tankii Alloy Material, ọ bụ ya mere e ji nwee ike ịrụ ọrụ ya nke ọma.Waya ọla kọpa 1.0mm nke a kpụrụ akpụỌ na-ejikọta uru abụọ dị mkpa: oke ike nke ọla kọpa uhie dị ọcha (ọkwa T2) na nchedo mgbochi ire ere nke mkpuchi tin 3-5μ nke ziri ezi. Ejiri usoro tinning ọkụ na-aga n'ihu nke Huona rụọ ya - nke nwere nlekota ọkpụrụkpụ oge na njikwa okpomọkụ - waya ahụ na-eme ka oyi akwa tin ahụ rapara n'otu aka ahụ na isi ọla kọpa siri ike nke 1.0mm, enweghị oghere ma ọ bụ ntụpọ dị gịrịgịrị. Ọ na-edozi isi ihe mgbu abụọ dị mkpa nke waya ọla kọpa gba ọtọ: mbelata ike nke oxidation kpatara na enweghị ike ịgbasa ya nke ọma, na-eme ka ọ bụrụ ihe dị mkpa maka njikọ eletriki chọrọ nkwụsi ike ogologo oge, nkpọkọta dị mfe, na iguzogide gburugburu ebe obibi mmiri/ụlọ ọrụ mmepụta ihe.

Asambodo Ọkọlọtọ na Ihe

- Ọkwa onye nduzi: T2 ọla kọpa uhie dị ọcha (dabere na GB/T 3956-2008; nke kwekọrọ na ASTM B33, IEC 60288 Klas 1)

- Tin mkpuchi Standard: GB/T 4910-2009, IEC 60317-2 (enweghị ndu: Pb ≤0.005%, Sn ≥99.9%)

- Asambodo Ogo: Dabara na RoHS 2.0, sistemụ njikwa mma ISO 9001, nkwenye nnwale gburugburu ebe obibi SGS

- Onye nrụpụtaIhe eji arụ ọrụ Tankii Alloy (afọ 15+ nke ahụmịhe nhazi ihe eji arụ ọrụ ọla kọpa)

Uru Arụmọrụ Isi

1. Onye na-eduzi ọla kọpa uhie dị ọcha: Nhazi na-enweghị atụ

- Ọgbakọ eletriki: ≥98% IACS (20℃), karịa ọla kọpa ejiri alloy mee (dịka ọmụmaatụ, alloys CuNi: ~20% IACS) na aluminom (61% IACS). Na-ahụ na obere voltaji dara na sekit voltaji dị ala (dịka ọmụmaatụ, waya ụgbọala 12V, eriri USB 5V) na nnyefe mgbama ngwa ngwa maka sensọ.

- Ọdịiche Mekaniki: Ogologo ≥30% (25℃) na ike nrụgide ≥200 MPa. Nwere ike iguzogide mgbagọ ugboro ugboro (nnwale mgbagọ 180° ≥ ugboro 10 na-agbajighị) maka waya n'ebe dị warara (dịka ọmụmaatụ, ngalaba dị n'ime ngwa, njikọ ọnụ PCB).

2. Mkpuchi Tin nke 3-5μ: Nchedo Ezubere Iche

- Mgbochi Mgbochi Oxidation: Okpukpu tin dị oke njọ na-egbochi ikuku/mmiri ka ọ ghara imetụ ọla kọpa aka, na-egbochi mmepụta nke copper oxide (CuO/Cu₂O). Ọbụna n'ime iru mmiri 80% ruo ọnwa 12, waya ahụ na-anọgide na-enwe ≥97% mbugharị mbụ (ma e jiri ya tụnyere copper gba ọtọ: ọ na-ada ruo 85% n'ime ọnwa 3).

- Mmeziwanye Njikọta: Ebe agbaze nke Tin dị ala (232℃) na-enye ohere "ịmị mmiri ozugbo" n'oge ịgbado ọkụ - ọ dịghị mkpa ka e hichaa ya tupu oge eruo ma ọ bụ mee ka ọ rụọ ọrụ. Na-ebelata oge nzukọ PCB site na 40% megide ọla kọpa efu (nke chọrọ iwepụ oxide site na iji ájá/kemikal).

- Nhazi ọkpụrụkpụ kwesịrị ekwesịỌkpụrụkpụ nke 3-5μ na-ezere oke abụọ: mkpuchi dị gịrịgịrị (<3μ) enweghị ike ikpuchi ntụpọ ọla kọpa, ebe mkpuchi dị arọ (>5μ) na-eme ka waya ahụ gbawaa agbawa (ọ na-agbawa agbawa mgbe a na-agbagọ).

Nkọwapụta Nkà na ụzụ

| Paramita | Uru zuru ezu |

| Dayameta Aha (N'ozuzu) | 1.0mm (onye na-eduzi: ~0.992-0.994mm; mkpuchi tin: 3-5μ) |

| Nnwale Dayameta | ±0.02mm |

| Ọkpụrụkpụ nke mkpuchi tin | 3μ (opekempe) – 5μ (oke); nha nhata ọkpụrụkpụ: ≥95% (enweghị ntụpọ <2.5μ) |

| Ọdụdọ eletriki (20℃) | ≥98% IACS |

| Ike ọdụdọ | 200-250 MPa |

| Ogologo oge na ezumike | ≥30% (L0 = 200mm) |

| Nrapado Tin | A naghị agbapụta/gbapụ mgbe mgbagọ 180° gasịrị (radius=5mm) + ule teepu (teepu 3M 610, enweghị ihe fọdụrụ na tin) |

| Nguzogide Nrụgide | Ọ gafere ule mmiri nnu ASTM B117 (awa 48, 5% NaCl, 35℃) - enweghị nchara uhie, tin ahụ na-agbapụta |

| Oke okpomọkụ ọrụ | -40℃ (okpomọkụ dị ala, enweghị mgbawa) ruo 105℃ (ojiji na-aga n'ihu, enweghị agbaze tin) |

Ngwa ahịa na nhazi ya

| ihe | Nkọwapụta |

| Fọm Ntinye | Onye nduzi siri ike (ọkọlọtọ); onye nduzi gbagọrọ agbagọ (omenala: 7/0.43mm, 19/0.26mm) |

| Nhazi Spool | 500m/1000m kwa spool (ihe eji eme ihe: ABS plastik, dayameta: 200mm, oghere isi: 50mm) |

| Mmecha Elu | Tin na-egbuke egbuke (ndabara adaba); tin matte (omenala, maka ngwa mgbochi ịcha ọkụ) |

| Ọgwụgwọ Ndị Ọzọ | Mkpuchi nhọrọ (PVC/XLPE/Silicone, ọkpụrụkpụ: 0.1-0.3mm, agba: ojii/ọbara ọbara/acha anụnụ anụnụ) |

| Nkwakọ ngwaahịa | Akpa foil aluminom nke e ji vacuum mechie (anaghị egbochi mmiri) + katọn mpụta (nwere ihe na-ekpo ọkụ, ihe na-egbochi mmetụta) |

Ihe Ndị A Na-ahụkarị Maka Ngwa

- Ngwa ụlọ: Waya dị n'ime maka igwe ịsa ákwà (anaghị eguzogide iru mmiri), friji (okpomọkụ dị ala), na oven microwave (okpomọkụ na-eguzogide ruo 105℃).

- Eletrọniki Ụgbọala: Ọdụ njikọ maka batrị ụgbọala (mgbochi ire ere), waya sensọ (mgbaàmà kwụsiri ike), na sistemụ infotainment n'ime ụgbọala (mbelata voltaji dị ala).

- PCB na Eletrọniki Ndị Ahịa: Ịsa ihe site n'oghere maka bọọdụ Arduino/Raspberry Pi, ndị na-eduzi eriri USB-C, na waya eriri LED (njikọ dị mfe).

- Njikwa Ụlọ Ọrụ: Wiring maka panel PLC (nguzogide iru mmiri ụlọ ọrụ) na obere ọkụ eletrik (obere mfu ike).

- Ngwaọrụ Ahụike: Waya dị n'ime maka ngwaọrụ nchọpụta ihe dị mfe ibugharị (enweghị ndu, na-agbaso ụkpụrụ biocompatibility) na obere ọkpọkọ ahụike (mgbagọ na-agbanwe agbanwe).

Nkwanyesi Ike Dị Mma site na Tankii Alloy Material

A na-enyocha otu waya ọla kọpa nke nwere iko 1.0mm ọ bụla n'ime ha:

- Nnwale Ọkpụrụkpụ Tin: ihe nyocha X-ray fluorescence (XRF) (nkezi: ±0.1μ) – isi ihe nlele ise kwa spool.

- Ule Nhazi: Ihe nnwale nyocha isi anọ (izizi: ±0.5% IACS) – ihe nlele atọ kwa otu.

- Nnwale Mekaniki: Igwe nnwale zuru ụwa ọnụ (nrụgide/ogologo) + ihe nnwale gbagọrọ agbagọ (njikọta) - ihe nlele abụọ kwa otu.

Ihe nlele efu (ogologo 1m, iberibe 2-3 kwa nkọwapụta) na Akụkọ Nnwale Ihe (MTR) zuru ezu dị ma ọ bụrụ na a rịọ ya. Ndị otu teknụzụ anyị na-enye nkwado otu-na-otu maka ihe achọrọ maka omenala (dịka ọmụmaatụ, nhọrọ ihe mkpuchi maka ngwa okpomọkụ dị elu, nhazi onye na-eduzi ihe maka waya na-agbanwe agbanwe).

Dee ozi gị ebe a zitere anyị ya

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu