Eriri eriri nke waya mgbochi FeCrAl nke 0.05mm

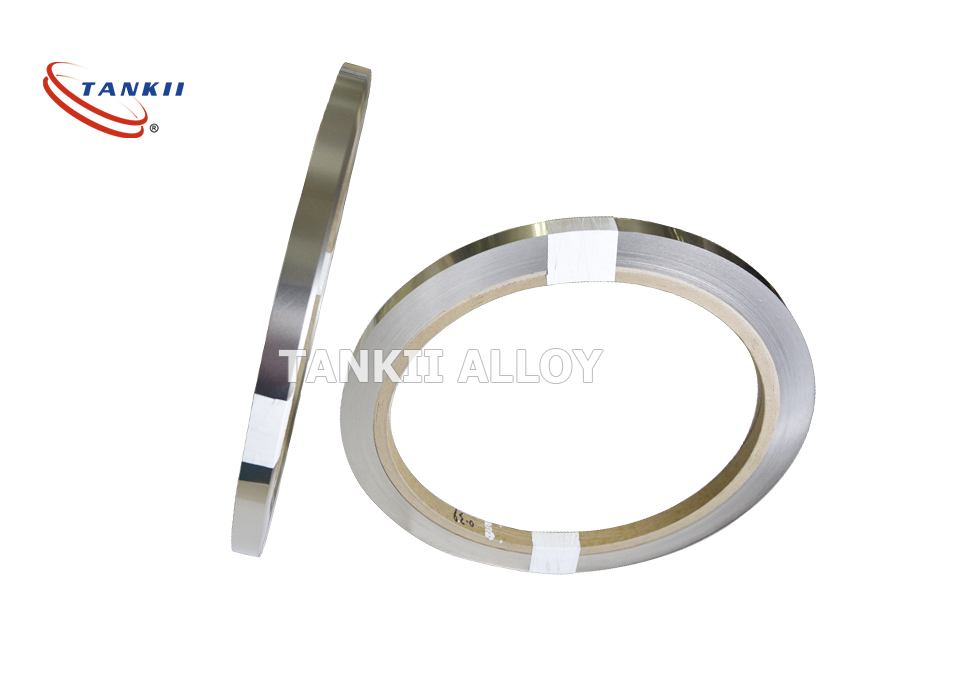

Alloy FeCrAlỌkpụrụkpụ nke Foil/Strip Coil 0.05mm maka ihe ndị e ji ọla mee maka mmanụ aṅụ

Oke ọdịnaya aluminom, yana oke ọdịnaya chromium na-eme ka okpomọkụ nke ihe ndị a na-eme ka ọ dị elu ruo 1425 C (2600F); N'okpuru isi okwu a, ihe ndị a na-eguzogide okpomọkụ.Ngwakọta FeCrAlA na-atụnyere s na ihe ndị a na-ejikarị eme ihe dịka Fe na Ni. Dịka a pụrụ ịhụ site na tebụl ahụ,Ngwakọta FeCrAls nwere ihe ndị ka mma ma e jiri ya tụnyere alloys ndị ọzọ dị na ọtụtụ gburugburu.

Ọ dị mkpa ịmara na, n'oge ọnọdụ okpomọkụ na-agbanwe agbanwe, mgbakwunye yttrium na alloy AF nke a makwaara dị ka alloy Fecralloys, na-eme ka nrapara nke oxide nchebe ka mma, na-eme ka ndụ ọrụ nke ihe ndị dị na alloy AF dị ogologo karịa nke ọkwa A-1.

A na-eji ígwè chromium aluminum alloy eme waya ndị a na-akpọ Fe-Cr-Al alloy, nke nwere obere ihe ndị na-emeghachi omume dịka yttrium na zirconium, a na-emepụtakwa ha site na ịgbaze ihe, ịpịgharị ígwè, ịkpụ ihe, ịchacha ihe, eserese, ọgwụgwọ elu, ule njikwa iguzogide ihe, wdg.

E ji igwe oyi akpaka dị elu kpụọ waya Fe-Cr-Al, nke kọmputa na-achịkwa ikike ike ya, ha dị ka waya na rịbọn (strip).

Atụmatụ na uru

1. Ọ bụrụ na okpomọkụ dị elu, okpomọkụ kachasị elu nwere ike iru 1400C (0Cr21A16Nb, 0Cr27A17Mo2, wdg.)

2. Ọnụọgụ okpomọkụ dị ala nke iguzogide

3. Ọ na-ebelata oke mgbasa okpomọkụ karịa Ni-base super-alloys.

4. Ike eletriki dị elu

5. Ezigbo iguzogide nchara n'okpuru oke okpomọkụ, ọkachasị n'okpuru ikuku nwere sulfide

6. Ibu elu dị elu

7. Na-eguzogide ihe na-akpụ akpụ

8. Ọnụ ego ihe eji arụ ọrụ dị ala, Njupụta dị ala na ọnụ ahịa dị ọnụ ala ma e jiri ya tụnyere waya Nichrome.

9. Nguzogide oxidation dị elu na 800-1300ºC

10. Ogologo ndụ ọrụ

Mmepụta nke usoro alumina metastable n'ihi oxidation nke azụmahịaNgwakọta FeCrAlA lere waya (ọkpụrụkpụ 0.5 mm) n'ọtụtụ okpomọkụ na oge. E jiri thermogravimetric analyzer (TGA) mee ka ihe nlele ndị ahụ dị n'ime ikuku site na iji ihe nyocha thermogravimetric (TGA). E jiri Electronic Scanning Electron Microscope (ESEM) nyochaa ọdịdị nke ihe nlele ndị a na-eme ka ha dị n'ime ikuku, e jirikwa ihe nyocha Energy Dispersive X-Ray (EDX) mee X-ray n'elu mmiri. E jiri usoro nke X-Ray Diffraction (XRD) kọwaa oge uto oxide. Ọmụmụ ihe ahụ dum gosiri na o kwere omume ịkụ gamma alumina dị elu n'elu mmiri.Ngwakọta FeCrAlelu waya mgbe e tinyere oxidation n'ime mmiri n'elu 800°C ruo ọtụtụ awa.

| Ígwè Chrome Aluminom | |||||||

| OCr25Al5 | CrAl25-5 | 23.0 | 71.0 | 6.0 | |||

| OCr20Al5 | CrAl20-5 | 20.0 | 75.0 | 5.0 | |||

| OCr27Al7Mo2 | 27.0 | 65.0 | 0.5 | 7.0 | 0.5 | ||

| OCr21Al6Nb | 21.0 | 72.0 | 0.5 | 6.0 | 0.5 | ||

| Ígwè Chrome Aluminom | ||

| OCr25Al5 | Enwere ike iji ya n'ọnọdụ ọrụ ruo 1350°C, mana ọ nwere ike imebi ya. | Ihe ndị na-ekpo ọkụ nke ọkụ ọkụ dị elu na ihe na-ekpo ọkụ na-egbuke egbuke. |

| OCr20Al5 | A na-eji ihe e ji kpụọ ferromagnetic nke a pụrụ iji mee ihe n'okpomọkụ ruo 1300°C. A ga-arụ ọrụ ya n'ebe kpọrọ nkụ iji zere ire ere. Ọ nwere ike ịgbaze ma ọ bụrụ na okpomọkụ dị elu. | Ihe ndị na-ekpo ọkụ nke ọkụ ọkụ dị elu na ihe na-ekpo ọkụ na-egbuke egbuke. |

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu