Mmiri eriri mmiri

pnkọwa ngwaahịa

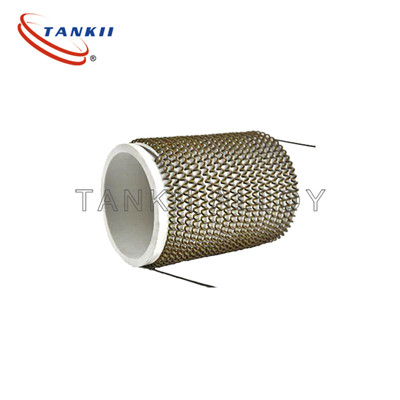

Ụlọ ọrụ anyị na-emepụta waya ígwè-chromium-aluminum na nickel-chromium dị elu, nke na-eji ike waya ọkụ eletrik na-achịkwa kọmputa ma igwe na-agbagharị ngwa ngwa na-agbagharị agbagharị. Njirimara nke ngwaahịa a: iguzogide okpomọkụ dị elu, ikpo ọkụ ngwa ngwa, ndụ ọrụ ogologo oge, iguzogide siri ike, obere mgbanwe ike, pitch otu mgbe agbatịchara, elu na-egbuke egbuke ma dị ọcha; a na-ejikarị ya eme ihe n'obere ọkụ eletrik, ọkụ muffle, ngwa ọkụ na ntụ oyi, oven dị iche iche, tubes ọkụ eletrik na ngwa ụlọ, wdg. Enwere ike ịmepụta ma mepụta ọtụtụ ogwe ọkụ ọkụ ụlọ ọrụ na nke obodo dịka mkpa onye ọrụ si dị.

| Ike W | Voltage V | Dayameta mm | OD mm | LBekee (Ntụaka) mm | Wg asatọ |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| narị isii | 220 | 0.40 | 4.2 | 228 | 6.1 |

| narị asatọ | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Okpomọkụ na ihe mejupụtara kemịkalụ nke waya kpo oku

| Ọkwa | Max. Na-aga n'ihu Ọnọdụ Ọrụ. | Cr% | Ni% | Al% | Fe% | Re% | Nb% | Mo% |

| Cr20Ni80 | 1200℃ | 20-23 | Bọl. |

|

|

|

|

|

| Cr30Ni70 | 1250℃ | 28~31 | Bọl. |

|

|

|

|

|

| Cr15Ni60 | 1150℃ | 15~18 | 55~61 |

| Bọl. |

|

|

|

| Cr20Ni35 | 1100℃ | 18~21 | 34~37 |

| Bọl. |

|

|

|

| TANKII APM | 1425℃ | 20.5~23.5 |

| 5.8 | Bọl. | / |

|

|

| 0Cr27Al7Mo2 | 1400℃ | 26.5~27.8 |

| 6~7 | Bọl. |

|

| 2 |

| 0Cr21Al6Nb | 1350℃ | 21~23 |

| 5~7 | Bọl. |

| 0.5 |

|

| 0Cr25Al5 | 1250℃ | 23~26 |

| 4.5~6.5 | Bọl. |

|

|

|

| 0Cr23Al5Y | 1300℃ | 22.5~24.5 |

| 4.2~5.0 | Bọl. |

|

|

|

| 0Cr19Al3 | 1100℃ | 18~21 |

| 3~4.2 | Bọl. |

|

|

|

Isi ihe ndị dị na teknụzụ nke waya alloy FeCrAl:

①Okpomọkụ ojiji dị elu, okpomọkụ ojiji nke waya alloy aluminum iron-chromium n'ime ikuku nwere ike iru 1300℃;

②Ogologo ndụ ọrụ;

③ Ibu elu a na-ekwe ka ọ dị ukwuu;

⑤Njide ike dị mkpa pere mpe karịa alloy nickel-chromium; ④Nguzogide oxidation dị mma, ihe nkiri AI2O3 nke e mepụtara mgbe oxidation gasịrị nwere ezigbo iguzogide kemịkalụ na nnukwu iguzogide;

⑥Nguzogide dị elu;

⑦Ọdịmma iguzogide sọlfọ dị mma;

⑧Ọnụ ahịa ya dị ala karịa nke nickel-chromium alloy;

⑨Ihe na-adịghị mma bụ na ka okpomọkụ na-arị elu, ọ na-egosipụta ike, ike ya na okpomọkụ dị elu dịkwa ala.

Njirimara nke waya stovu eletrik nickel-chromium bụ:

① Ike dị elu na okpomọkụ dị elu;

②Jisie ike mgbe ejiri ya ogologo oge, ihe ahụ agaghị agbawa agbawa;

③Mgbapụta nke Ni-ming alloy nke oxidized zuru oke dị elu karịa nke Fe-Cr-Al alloy;

④Ọ dịghị magnetism;

⑤Ewezuga ikuku sọlfọ, ọ nwere nguzogide nchara ka mma

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu