Nguzogide eletriki gbara okirikiri CuNi Alloy 1 – 5 Mohm Maka ihe ndị na-ekpo ọkụ ikuku

Nguzogide Eletriki Gbara Gburugburu Nicr Alloy 1 – 5 Mohm Maka Ihe Ndị Na-ekpo Ọkụ nke Igwe Ọkụ

1. Nkọwa Izugbe Ihe

Kọnstantanbụ ihe eji emepụta ọla kọpa-nickel nke a makwaara dịkaEureka,Ọganihu, naỤgbọ mmiriỌ na-abụkarị 55% ọla kọpa na 45% nickel. Isi ihe dị na ya bụ iguzogide ya, nke na-adịgide adịgide n'ọtụtụ okpomọkụ dị iche iche. A maara alloys ndị ọzọ nwere obere okpomọkụ yiri nke ahụ, dị ka manganin (Cu)86Mn12Ni2).

Maka nha nke nnukwu ụdị nje, 5% (50 000 microstrian) ma ọ bụ karịa, annealed constantan (P alloy) bụ ihe grid a na-ahọrọkarị. Constantan n'ụdị a dị oke mma.ductile; na, n'ogologo nha nha nke 0.125 inch (3.2 mm) na karịa, enwere ike ịbelata ruo >20%. Agbanyeghị, ekwesịrị iburu n'uche na n'okpuru ụdị nrụgide dị elu, P alloy ga-egosipụta mgbanwe nrụgide na-adịgide adịgide na okirikiri ọ bụla, ma mee ka ọ dakọọ.efumgbanwe na nha nrụgide. N'ihi njirimara a, na ọchịchọ maka ọdịda grid tupu oge eruo na nrụgide ugboro ugboro, a naghị akwado P alloy maka ojiji nke nrụgide cyclic. A na-enweta P alloy nwere nọmba STC nke 08 na 40 maka ojiji na ọla na plastik, n'otu n'otu.

2. Okwu Mmalite Oge Opupu na Ngwa

Mmiri ntụgharị gburugburu, ma ọ bụ mmiri ntutu isi, n'ime elekere mkpu.

Mmiri dị oke elu. Mgbe a na-akpakọ eriri ndị ahụ, ha na-amịkọrọ ibe ha, nke mere ka ha nwee ike ịga ogologo oge.

Mmiri ọkụ kwụ ọtọ nke tankị Stuart

Mgbatị nrụgide na-apụta n'ime ngwaọrụ ntụgharị ahịrị a kpọchiri akpọchi.

Ogwe torsion gbagọrọ agbagọ n'okpuru ibu

Mmiri akwụkwọ n'elu gwongworo

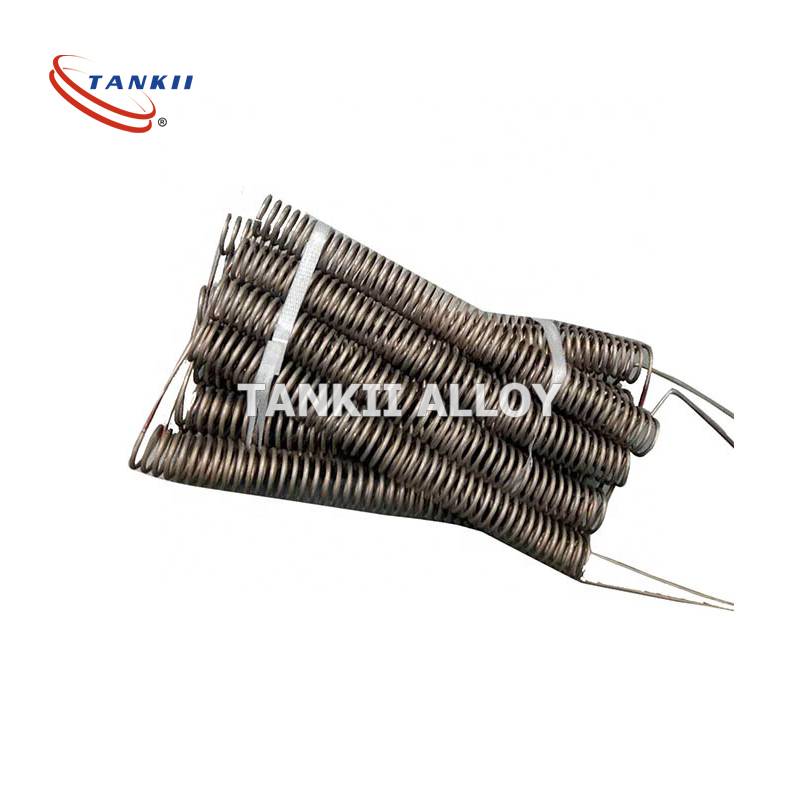

Enwere ike kewaa Springs dabere n'otú esi etinye ike ibu n'ọrụ ha:

Mmiri nrụgide/mgbatị - e mere mmiri ahụ ka ọ rụọ ọrụ na ibu nrụgide, yabụ mmiri ahụ na-agbatị ka a na-etinye ibu ahụ na ya.

Mmiri mkpakọ - emebere ya ka ọ rụọ ọrụ na ibu mkpakọ, yabụ mmiri ahụ na-adị mkpụmkpụ ka a na-etinye ibu ahụ na ya.

Mmiri Torsion - n'adịghị ka ụdị ndị dị n'elu ebe ibu ahụ bụ ike axial, ibu etinyere na mmiri torsion bụ ike torsion ma ọ bụ ike ntụgharị, njedebe nke mmiri ahụ na-agbagharị site n'akụkụ ka a na-etinye ibu ahụ.

Ibu a na-akwado mgbe niile - nke a na-anọgide otu ihe ahụ n'oge okirikiri ntụgharị.

Mmiri na-agbanwe agbanwe - iguzogide nke eriri iji buo ibu na-agbanwe n'oge mkpakọ.

Mmiri siri ike dị iche iche - ike nke eriri igwe ibu nwere ike ịdị iche iche dịka ọmụmaatụ site na sistemụ njikwa, ụfọdụ ụdị nke isi iyi ndị a na-agbanwekwa ogologo ha si otú a na-enye ikike ime ihe.

A pụkwara ikewa ha dịka ọdịdị ha si dị:

Mmiri dị larịị - ụdị a bụ nke e ji ígwè dị larịị mee.

Mmiri eji igwe eme - a na-emepụta ụdị mmiri a site na iji igwe eji lathe na/ma ọ bụ igwe eji egwe ihe kama iji igwe eji egwe ihe. Ebe ọ bụ na a na-eji ya eme ihe, mmiri nwere ike ịnwe atụmatụ na mgbakwunye na ihe na-agbanwe agbanwe. Enwere ike ime mmiri eji igwe eme ihe n'ọnọdụ ibu nkịtị dịka mkpakọ/mgbatị, torsion, wdg.

Mmiri serpentine - waya dị oke ibu nke a na-ejikarị eme ihe n'ime ihe ndina/ihe eji achọ mma nke oge a.

3. Ihe mejupụtara kemịkalụ na ihe onwunwe bụ isi nke Cu-Ni Low Resistance Alloy

| NjirimaraGrade | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Isi ihe mejupụtara kemịkalụ | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bọọl | Bọọl | Bọọl | Bọọl | Bọọl | Bọọl | |

| Oke Okpomọkụ Ọrụ Na-aga n'ihu (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ndozi ike na 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Njupụta (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Ọgbakọ okpomọkụ (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Ike nrụgide (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Ebe Mgbaze Dị Ihe Dị Ka Ya (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Nhazi Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | |

| Njirimara Magnetik | abụghị | abụghị | abụghị | abụghị | abụghị | abụghị | |

| NjirimaraGrade | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Isi ihe mejupụtara kemịkalụ | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bọọl | Bọọl | Bọọl | Bọọl | Bọọl | Bọọl | |

| Oke Okpomọkụ Ọrụ Na-aga n'ihu (oC) | 300 | 300 | 300 | 350 | 350 | narị anọ | |

| Ndozi ike na 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Njupụta (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Ọgbakọ okpomọkụ (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Ike nrụgide (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Ebe Mgbaze Dị Ihe Dị Ka Ya (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Nhazi Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | |

| Njirimara Magnetik | abụghị | abụghị | abụghị | abụghị | abụghị | abụghị | |

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu