Nnọọ na weebụsaịtị anyị!

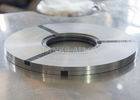

Nguzogide Na-egbuke egbuke Mpempe Akwụkwọ Dị larịị 5mm Obosara 1Cr13Al4 Waya nguzogide FeCrAl

1Cr13Al4 FeCrAl alloy Bright Flat Strip/Wide Strip maka ojiji nke Resistors

Ahọpụtala ihe ndị dị ka Fecral Alloys na Nickel-chromium alloys ka ha bụrụ ihe na-eguzogide ọgwụ maka resistor agbakwunyere n'ihi na ihe ndị dị na nickel-chromium alloys nwere nnukwu resistor eletriki nke a na-ejikarị eme ihe maka resistor fim dị gịrịgịrị [1, 2]. Nguzogide mpempe akwụkwọ nke ihe nkiri nickel-chrome alloy nke nwere 20% chromium nwere ike ịdị elu ruo 2-3 kilo ohms ma ka na-anọgide na-enwe ezigbo nkwụsi ike. Oke okpomọkụ nke 1 nke resistor (TCR) maka ihe ndị dị na nickel-chrome alloy dị ihe dị ka 110 ppm/°C. Site na itinye obere silicon na aluminom na nickel-chromium, a na-eme ka ọnọdụ okpomọkụ ka mma.

Ngwa:

Ihe mgbochi ndị e tinyere n'ime bọọdụ waya e biri ebi ga-abụ ihe na-eme ka ngwugwu dị obere ma nwee ntụkwasị obi dị elu ma melite arụmọrụ eletriki. Ijikọta ọrụ ihe mgbochi na ihe mgbochi na-eme ka mpaghara elu PWB nke ihe ndị dị iche iche na-eri na-eme ka ọrụ ngwaọrụ dịkwuo elu site na itinye ihe ndị ka na-arụ ọrụ. Ihe mgbochi nickel-chromium nwere nnukwu ike iguzogide eletriki, nke na-eme ka ha baa uru maka ojiji n'ọtụtụ ngwa. A na-ejikọta nickel na chromium na silicon na aluminom iji melite nkwụsi ike okpomọkụ ma belata oke ike nke iguzogide okpomọkụ. A na-etinye oyi akwa mgbochi siri ike nke fim dabere na alloys nickel-chromium mgbe niile na mpịakọta nke foil ọla kọpa iji mepụta ihe maka ngwa mgbochi agbakwunyere. Enwere ike ịcha akwa mgbochi siri ike nke dị gịrịgịrị nke dị n'etiti ọla kọpa na laminate iji mepụta ihe mgbochi pụrụ iche. Chemicals maka ịkpụcha bụ ihe a na-ahụkarị na usoro mmepụta PWB. Site na ijikwa ọkpụrụkpụ nke alloys, a na-enweta uru mgbochi mpempe akwụkwọ site na 25 ruo 250 ohm/sq. Akwụkwọ a ga-atụnyere ihe nickel-chromium abụọ na usoro ịkpụcha ha, otu nha, njikwa ike, arụmọrụ okpomọkụ, njikọta na mkpebi ịkpụcha.

Ihe mgbochi ndị e tinyere n'ime bọọdụ waya e biri ebi ga-abụ ihe na-eme ka ngwugwu dị obere ma nwee ntụkwasị obi dị elu ma melite arụmọrụ eletriki. Ijikọta ọrụ ihe mgbochi na ihe mgbochi na-eme ka mpaghara elu PWB nke ihe ndị dị iche iche na-eri na-eme ka ọrụ ngwaọrụ dịkwuo elu site na itinye ihe ndị ka na-arụ ọrụ. Ihe mgbochi nickel-chromium nwere nnukwu ike iguzogide eletriki, nke na-eme ka ha baa uru maka ojiji n'ọtụtụ ngwa. A na-ejikọta nickel na chromium na silicon na aluminom iji melite nkwụsi ike okpomọkụ ma belata oke ike nke iguzogide okpomọkụ. A na-etinye oyi akwa mgbochi siri ike nke fim dabere na alloys nickel-chromium mgbe niile na mpịakọta nke foil ọla kọpa iji mepụta ihe maka ngwa mgbochi agbakwunyere. Enwere ike ịcha akwa mgbochi siri ike nke dị gịrịgịrị nke dị n'etiti ọla kọpa na laminate iji mepụta ihe mgbochi pụrụ iche. Chemicals maka ịkpụcha bụ ihe a na-ahụkarị na usoro mmepụta PWB. Site na ijikwa ọkpụrụkpụ nke alloys, a na-enweta uru mgbochi mpempe akwụkwọ site na 25 ruo 250 ohm/sq. Akwụkwọ a ga-atụnyere ihe nickel-chromium abụọ na usoro ịkpụcha ha, otu nha, njikwa ike, arụmọrụ okpomọkụ, njikọta na mkpebi ịkpụcha.

Ihe alloy

usoro ngwaahịa ndị ọzọ:

FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

NiCr Alloy: Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Welding waya: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

Ngwakọta thermocouple: K, J, E, T, N, S, R, B, KX, JX, EX, TX, NX.

Ihe mejupụtara Inconel: Inconel 600,601,617,X-750,625,690,718,825.

Ngwakọta ihe eji eme ihe: Incoloy 800,800H,800HT,825,925.

Hastelloy alloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

Alloy Monel: Monel 400,K500.

Alloy dị elu nke nwere okpomọkụ: A-286,Nimonic80A/90,GH131,GH1140,GH36,GH2706,GH2901,GH3625,GH3536,GH4169.

Usoro alloy nke a kapịrị ọnụ: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Ihe mkpuchi mmiri ọkụ: Inconel 625, Ni95Al5, Monel400,45CT,HC-276,K500,Cr20Ni80.

usoro ngwaahịa ndị ọzọ:

FeCrAl Alloy: OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb,0Cr27Al7Mo2.

NiCr Alloy: Cr20Ni80,Cr30Ni70,Cr20Ni35,Cr20Ni30,Cr15Ni60.

CuNi Alloy: NC003,NC010,NC012,NC015,NC020,NC025,NC030,NC040,NC050,Constantan,6J8/11/12/13/.

Welding waya: ERNiCrMo-3/4/13,ERNiCrFe-3/7,ERNiCr-3/7,ERNiCu-7,ERNi-1, ER70S-6.

Ngwakọta thermocouple: K, J, E, T, N, S, R, B, KX, JX, EX, TX, NX.

Ihe mejupụtara Inconel: Inconel 600,601,617,X-750,625,690,718,825.

Ngwakọta ihe eji eme ihe: Incoloy 800,800H,800HT,825,925.

Hastelloy alloy: HC-276,C-22,C-4,HB,B/2/3,X,N.

Alloy Monel: Monel 400,K500.

Alloy dị elu nke nwere okpomọkụ: A-286,Nimonic80A/90,GH131,GH1140,GH36,GH2706,GH2901,GH3625,GH3536,GH4169.

Usoro alloy nke a kapịrị ọnụ: 1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Ihe mkpuchi mmiri ọkụ: Inconel 625, Ni95Al5, Monel400,45CT,HC-276,K500,Cr20Ni80.

Dee ozi gị ebe a zitere anyị ya

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu