Nnọọ na weebụsaịtị anyị!

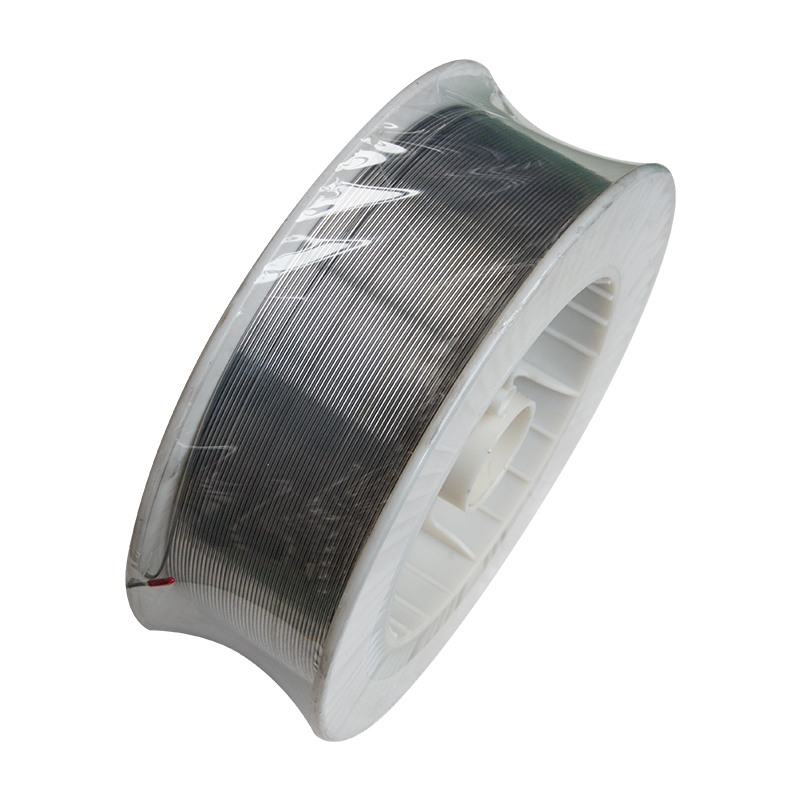

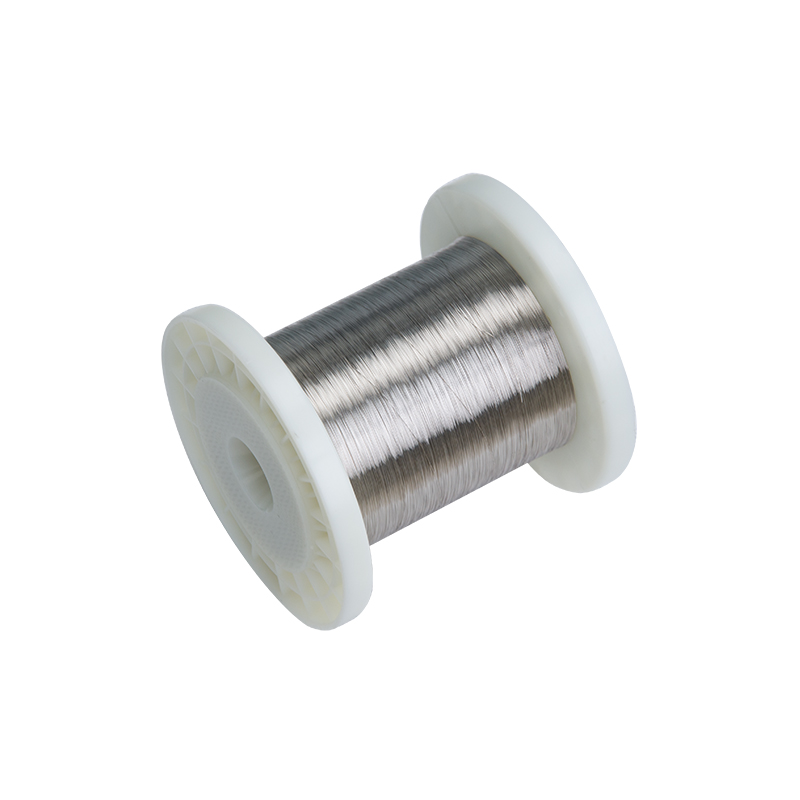

Waya Nickel Alloy Iron maka Ikpuchi Iko

Waya Nickel Alloy Iron maka Ikpuchi Iko

Nhazi: obere ihe nke alloy mgbasawanye okpomọkụ

Ngwa: A na-eji Invar eme ihe ebe achọrọ nkwụsi ike dị elu, dịka ngwa ọrụ ziri ezi, elekere, ihe nlele seismic creep, fremu ihe mkpuchi ihu telivishọn, valvụ na moto, na elekere antimagnetic. N'ịnyocha ala, mgbe a ga-eme nhazi elu nke mbụ (nke ziri ezi), a na-eji Invar eme mkpanaka nhazi nke ejiri mee ihe, kama osisi, fiberglass, ma ọ bụ ọla ndị ọzọ. E jiri Invar struts mee ụfọdụ piston iji belata mgbasawanye okpomọkụ ha n'ime silinda ha.

Ihe mejupụtara kemịkalụ na %, Invar

| Ni 35-37% | Fe . | C 0.05% | Si 0.3% | Mn 0,3-0,6% | S o 0.015% |

| P 0.015% | Mo 0.1% | V 0.1% | Al 0.1% | Cu 0.1% | Cr 0.15% |

![]()

![]()

![]()

| Oke okpomọkụ/ºC | 1/10-6ºC-1 | Oke okpomọkụ/ºC | 1/10-6ºC-1 |

| 20~-60 | 1.8 | 20-250 | 3.6 |

| 20~-40 | 1.8 | 20-300 | 5.2 |

| 20~-20 | 1.6 | 20-350 | 6.5 |

| 20~0 | 1.6 | 20-400 | 7.8 |

| 20-50 | 1.1 | 20-450 | 8.9 |

| 20~100 | 1.4 | 20-500 | 9.7 |

| 20~150 | 1.9 | 20~550 | 10.4 |

| 20-200 | 2.5 | 20-600 | 11 |

![]()

![]()

![]()

![]()

Dee ozi gị ebe a zitere anyị ya

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu