Nnọọ na weebụsaịtị anyị!

Waya ịgbado ọkụ nke ọla kọpa Phosphor Bronze-C/Ercusn-C/Scu5210

Ngwakọta kemịkalụ:

| Onye isi ụlọ ọrụ ọkọlọtọ | Nhazi ọkwa nọmba | Alloy nọmba | Cu | AI | Fe | Mn | Ni | P | Pb | Si | Sn | Zn | Mkpokọta ego nke ihe ndị ọzọ |

| ISO24373 | Cu5210 | CuSn8P | bọọlụ. | - | 0.1 | - | 0.2 | 0.01-0.4 | 0.02 | - | 7.5-8.5 | 0..2 | 0.2 |

| GB/T9460 | SCu5210 | CuSn8P | bọọlụ. | - | kachasị 0.1 | - | kachasị 0.2 | 0.01-0.4 | kachasị 0.02 | - | 7.5-8.5 | kachasị 0.2 | kachasị 0.2 |

| BS EN14640 | Cu5210 | CuSn9P | bọọlụ. | - | 0.1 | - | - | 0.01-0.4 | 0.02 | - | 7.5-8.5 | 0.2 | 0.5 |

| AWS A5.7 | C52100 | ERCuSn-C | bọọlụ. | 0.01 | 0.10 | - | - | 0.10-0.35 | 0.02 | - | 7.5-8.5 | 0.2 | 0.50 |

Njirimara anụ ahụ nke ihe:

| Njupụta | Kg/m3 | 8.8 |

| Oke agbaze | ºC | 875-1025 |

| Ọkwa okpomọkụ | W/mK | 66 |

| Ọdụ eletriki na-eduzi | Sm/mm2 | 6-8 |

| Ọnụọgụ nke mgbasawanye okpomọkụ | 10-6/K(20-300ºC) | 18.5 |

Ụkpụrụ ọkọlọtọ nke ígwè weld:

| Ogologo | % | 20 |

| Ike ọdụdọ | N/mm² | 260 |

| Ọrụ mmetụta mmanya a ma ama | J | 32 |

| Ike siri ike nke Brinell | HB 2.5/62.5 | 80 |

Ngwa:

A na-eji ígwè ọla kọpa tin nke nwere pasentị tin dị elu eme ihe, nke siri ike karịa maka ịgbado ọkụ. Ọ dabara nke ọma maka ịgbado ọkụ nke ihe ọla kọpa, dịka ọla kọpa, ọla kọpa tin, karịsịa maka ijikọ ihe ọla kọpa zinc alloys na ígwè. Ọ dị mma maka ịrụzi ịgbado ọkụ nke ọla kọpa a kpụrụ akpụ na maka ịgbado ọkụ na oven. Maka ịgbado ọkụ nke ọtụtụ oyi akwa na ígwè, a na-atụ aro ịgbado ọkụ arc pulsed. Maka nnukwu ọrụ, a na-atụ aro ka a na-ekpo ọkụ tupu oge eruo.

Techaa:

Dayameta:0.80 – 1.00 – 1.20 – 1.60 -2.40

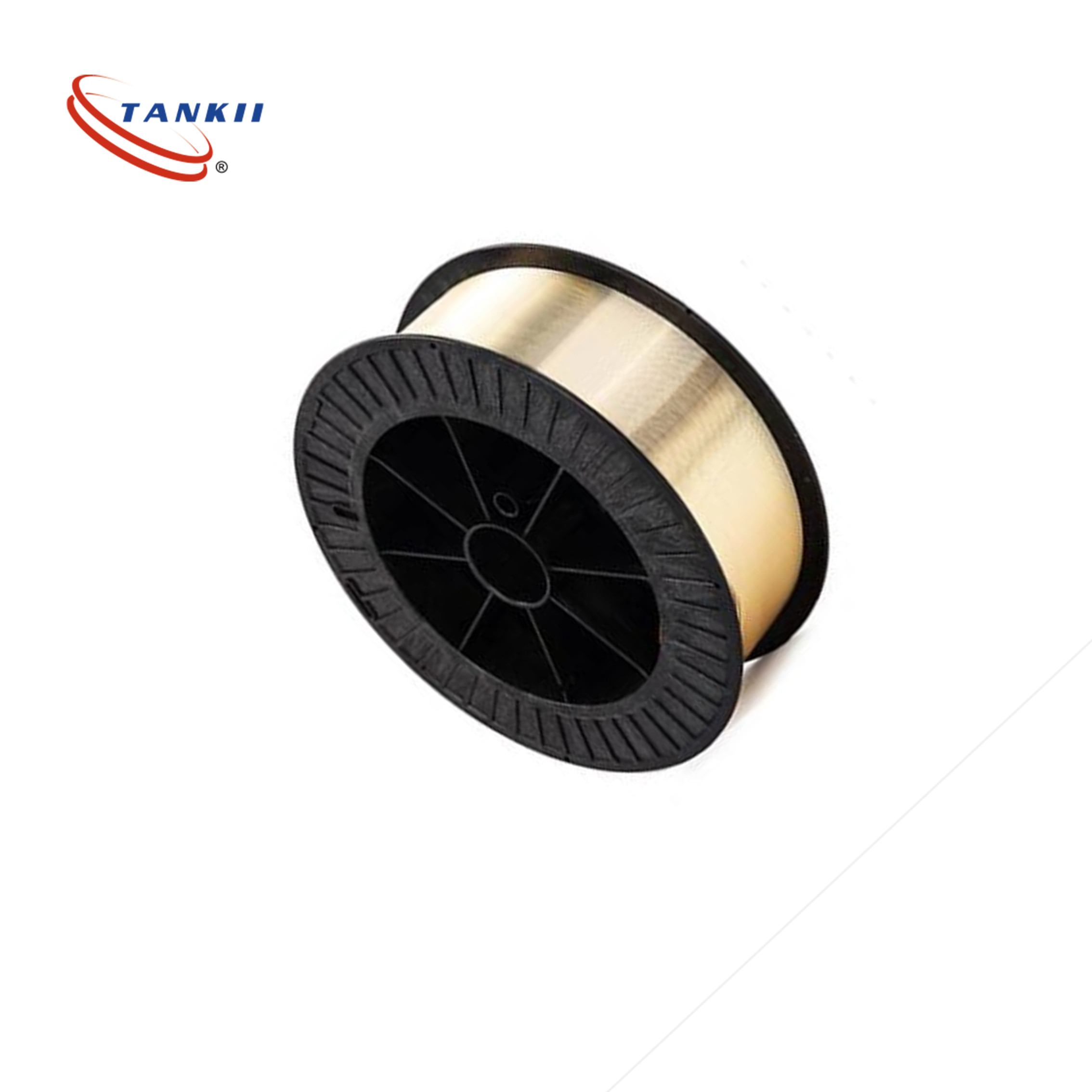

Spools: D100, D200, D300, K300, KS300, BS300

Mkpanaka: 1.20 – 5.0 mm x 350mm-1000 mm

Electrodes dị.

Ị ga-eme ihe ndị ọzọ ma ọ bụrụ na ị rịọrọ ya.

Dee ozi gị ebe a zitere anyị ya

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu