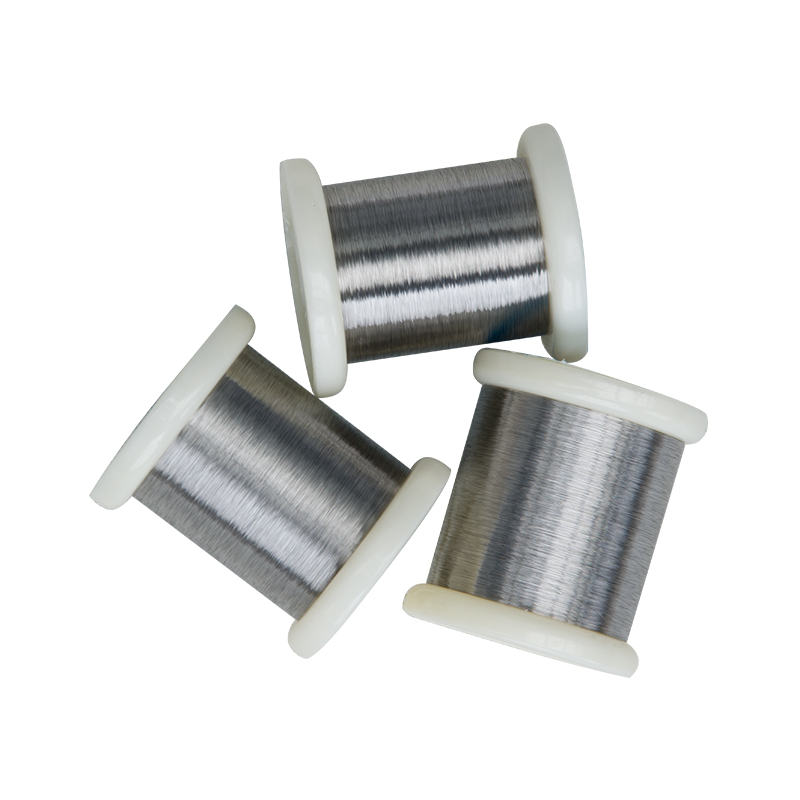

Nickel Alloy Hastelloy C276 Ernicrmo-4 Ịgbado ọkụ MIG TIG Ịgbado ọkụ Inconel C-276 C22, B3, B2 Waya

Hastelloy bụ ihe na-eguzogide nchara nke dabere na nickel, nke kewara n'ụzọ abụọ: ihe na-eguzogide nchara nke nickel-chromium na ihe na-egbochi nchara nke nickel-chromium-molybdenum. Hastelloy nwere ezigbo iguzogide nchara na nkwụsi ike okpomọkụ, a na-ejikwa ya eme ihe karịsịa n'ụgbọelu, ubi kemịkalụ, wdg.

ERNiCrMo-4A na-eji ya eme ihe maka ịgbado ọkụ gas-tungsten-arc na gas-metal-arc nke Inconel alloy C-276 na alloys nickel-chromium-molybdenum ndị ọzọ. N'ihi nnukwu ọdịnaya molybdenum, alloy a na-enye ezigbo iguzogide mgbawa nrụrụ na mgbawa na mgbawa na mgbawa mgbawa.

Aha ndị a na-akpọkarị: Oxford Alloy® C-276 FM C-276 Techalloy 276

Ọkọlọtọ: AWS A5.14,ERNiCrMo-4/ ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Europe NiCrMo16Fe6W4

Nha: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

| Ọkwa | C276 | C22 | C4 | N | |||

|

Kemikal Ihe mejupụtara ya (%) | C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

| Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 | |

| Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 | |

| P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | – | ≤0.015 | |

| S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | – | ≤0.02 | |

| Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 | |

| Ni | izu ike | izu ike | izu ike | izu ike | ≥65 | izu ike | |

| Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 | |

| Ti+Cu | – | – | ≤0.7 | – | ≤0.4 | ≤0.35 | |

| Al+Ti | – | – | – | – | ≤0.5 | ≤0.5 | |

| Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 | |

| Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 | |

| B | – | – | – | – | – | ≤0.01 | |

| W | 3-4.5 | 2.5-3.5 | – | – | ≤3 | ≤0.5 | |

| V | ≤0.35 | ≤0.35 | – | 0.2-0.4 | – | ≤0.5 | |

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu