Inconel Alloy 625 718 600 Waya Uns N06625 Fine/Filler/Waya ịgbado ọkụ

Inconel bụ ezinụlọ nke austenitic nickel chromium nke nwere super alloys.

Alloys Inconel bụ ihe ndị na-eguzogide corrion oxidation nke ọma maka ọrụ n'ebe dị oke njọ nke nwere nrụgide na nsogbu.

okpomọkụ. Mgbe a kpụchara Inconel ọkụ, ọ na-emepụta oyi akwa oxide siri ike, nke na-egbochi elu ya ka ọ ghara ịwakpo ọzọ. Inconel na-ejigide

ike n'elu oke okpomọkụ dị iche iche, na-adọrọ adọrọ maka ngwa okpomọkụ dị elu ebe aluminom na ígwè ga-adaba na ịrị elu

n'ihi oghere kristal e tinyere n'ọkụ. A na-emepụta ike okpomọkụ dị elu nke Inconel site na ngwọta siri ike.

ike ma ọ bụ mmiri ozuzo siri ike, dabere na alloy ahụ.

Inconel 718 bụ ihe eji emepụta nickel-chromium-molybdenum nke e mere iji guzogide ọtụtụ gburugburu ebe obibi na-emebi emebi nke ukwuu, mbibi na mmebi oghere. Ihe eji emepụta nickel ígwè a na-egosipụtakwa nnukwu mmepụta, nrụgide, na ihe ndị na-akpata mbibi n'oge okpomọkụ dị elu. A na-eji ihe eji emepụta nickel a site na okpomọkụ cryogenic ruo ọrụ ogologo oge na 1200° F. Otu n'ime ihe ndị pụrụ iche nke ihe mejupụtara Inconel 718's bụ mgbakwunye nke niobium iji mee ka ike dị ogologo nke na-enye ohere ịgbado ọkụ na ịgbado ọkụ na-enweghị ike mberede n'oge okpomọkụ na oyi. Mgbakwunye nke niobium na-arụ ọrụ na molybdenum iji mee ka matriks nke alloy sie ike ma nye ike dị elu na-enweghị ọgwụgwọ okpomọkụ na-eme ka ọ sie ike. Ihe ndị ọzọ a ma ama na nickel-chromium alloys na-eme ka ike dị ogologo site na mgbakwunye nke aluminum na titanium. A na-emepụta ihe eji emepụta nickel ígwè a ngwa ngwa ma enwere ike ịgbado ọkụ n'ọnọdụ annealed ma ọ bụ mmiri ozuzo (oge). A na-eji superalloy a eme ihe n'ọtụtụ ụlọ ọrụ dị iche iche dịka ụgbọelu, nhazi kemịkalụ, injinịa mmiri, akụrụngwa njikwa mmetọ, na ihe ndị na-emepụta nuklia.

Ihe ndị dị n'ime ya dị elu, dịka agụba turbine, vane nduzi, diski turbine, diski nrụgide dị elu, ụlọ nrụpụta igwe na ebe ọkụ na-ere ọkụ nke e ji emepụta turbine gas, ụgbọ mmiri na ụlọ ọrụ mmepụta ihe.

| ihe | Inconel 600 | Inconel | Inconel 617 | Inconel | Inconel | Inconel | Inconel | |

| 601 | 690 | 718 | X750 | 825 | ||||

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6~10 | izu ike | ≤3 | izu ike | 7~11 | izu ike | 5~9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | – | – | – | – | – |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | – | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥7.2 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

| Co | – | – | 10~15 | ≤10 | – | ≤1 | ≤1 | – |

| Al | – | 1-1.7 | 0.8-1.5 | ≤0.8 | – | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | – | – | ≤0.6 | ≤1.15 | – | – | 2.25-2.75 | 0.6-1.2 |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | – | – | – | 4.75-5.5 | – | 4.75-5.5 | 0.7-1.2 | – |

| Mo | – | – | 8~10 | 2.8-3.3 | – | 2.8-3.3 | – | 2.5-3.5 |

| B | – | – | ≤0.006 | – | – | – | – | – |

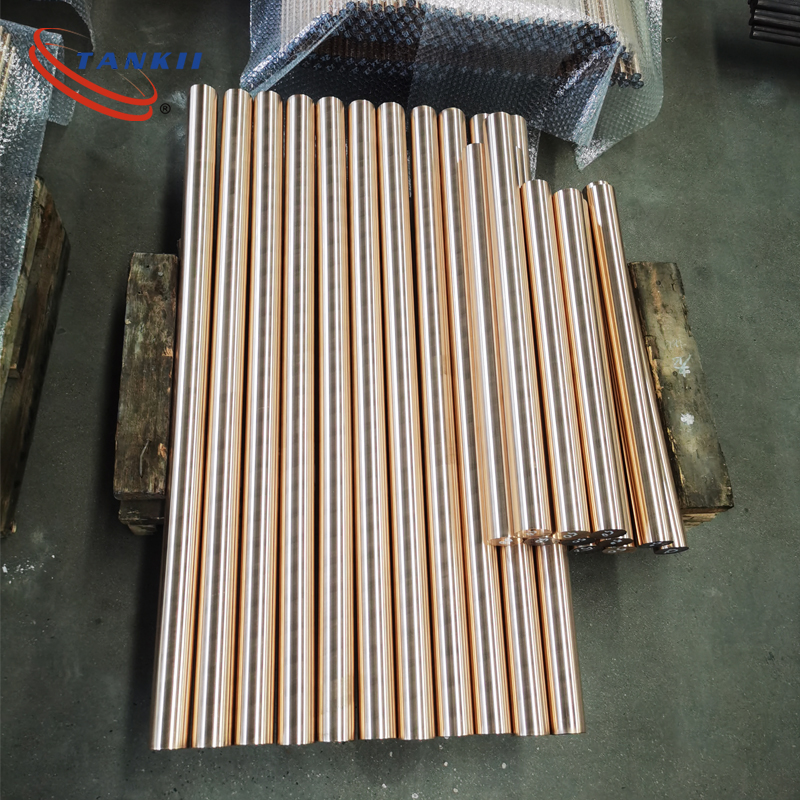

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu