Nnọọ na weebụsaịtị anyị!

Dị na Ngwaahịa Dị Elu ТБ2013/TM-2/108SP Bimetallic Strip maka Njikwa Oge Okpomọkụ

Nkọwa Ngwaahịa

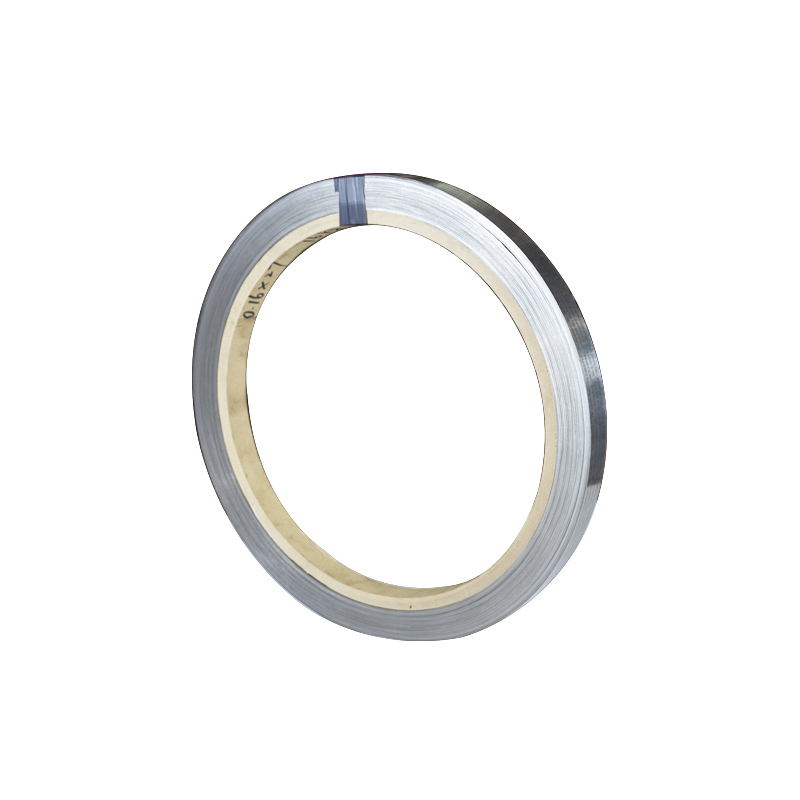

ТБ2013/TM-2/108SP Bimetallic Strip

Nchịkọta Ngwaahịa

TTEB2013/TM-2/108SP bimetallic stripe, otu ihe mejupụtara ọrụ dị elu nke Tankii Alloy Material mepụtara ma mepụta, bụ ọkwa pụrụ iche nke emebere maka ọnọdụ okpomọkụ dị n'etiti ruo elu. Ejiri alloys abụọ dị iche iche mee ya na coefficients mgbasa okpomọkụ a na-achịkwa nke ọma - nke ejiri teknụzụ mgbasa ọkụ na-agbagharị ọkụ nke Huona mee - eriri a na-ejikọta uru atọ dị mkpa: nzaghachi okpomọkụ kwụsiri ike, iguzogide ike ọgwụgwụ igwe dị mma, na mgbanwe gburugburu ebe obibi sara mbara. N'adịghị ka eriri bimetallic nkịtị, a haziri ọkwa TTEB2013/TM-2/108SP iji dozie mmetụta okpomọkụ na ike nhazi, na-eme ka ọ dị mma maka thermostats ụlọ ọrụ mmepụta ihe, ihe nchebe okpomọkụ oke moto, na akụkụ nkwụghachi okpomọkụ ziri ezi na gburugburu ọrụ siri ike (dịka ọmụmaatụ, oke iru mmiri, ịma jijiji).

Nhazi ọkọlọtọ na ihe mejupụtara isi

- Ọkwa Ngwaahịa: ТБ2013/TM-2/108SP

- Nhazi nke Ngwakọta: Ọ na-abụkarị "oyi akwa mmụba dị elu" na "oyi akwa mmụba dị ala"; ike njikọ ihu ≥140 MPa

- Ụkpụrụ Ndị Na-agbaso: Na-agbaso GOST 28561-90 (ọkọlọtọ Russia maka mpempe bimetallic) na IEC 60694 maka ihe ndị na-achịkwa okpomọkụ; dakọtara na ihe EU chọrọ RoHS

- Onye Mmepụta: Tankii Alloy Material, nke a kwadoro dịka ISO 9001 na ISO 14001 si dị, nwere usoro alloy dị n'ime ụlọ na ikike njikọ dị iche iche iji kwekọọ na ihe achọrọ maka arụmọrụ ọkwa ahụ.

Uru Ndị Dị Mkpa (na nke Mkpụrụ Bimetallic General)

ТБ2013/TM-2/108SP pụtara ìhè maka arụmọrụ ya nke lekwasịrị anya na ngwa, na-edozi nsogbu ndị dị na ojiji ụlọ ọrụ mmepụta ihe na gburugburu ebe obibi siri ike:

- Ngbanwe Okpomọkụ sara mbara: Ọ na-arụ ọrụ nke ọma n'ime -50℃ ruo 250℃ (ojiji na-aga n'ihu), yana nguzogide nwa oge ruo 300℃—nke karịrị mpempe bimetallic ọkọlọtọ (ejedebere na ≤200℃) ma dabara adaba maka ọnọdụ ụlọ ọrụ mmepụta ihe dị elu (dịka ọmụmaatụ, sensọ nke injin).

- Obere Hysteresis Okpomọkụ: Njehie Hysteresis ≤3℃ (n'etiti ebe a na-eme ka okpomọkụ na oyi dị jụụ) na 150℃—dị oke mkpa maka njikwa okpomọkụ ziri ezi (dịka ọmụmaatụ, thermostats oven ụlọ ọrụ mmepụta ihe) ebe okirikiri mgbanwu/mgbanyụ ugboro ugboro chọrọ oke kwesịrị ekwesị.

- Ike Ike Ike: Na-eguzogide usoro okpomọkụ ≥15,000 (-50℃ ruo 250℃) na-enweghị mmebi ihu ma ọ bụ mmebi arụmọrụ - ndụ ọrụ 3× dị ogologo karịa mpempe akwụkwọ dị ala, na-ebelata ọnụ ahịa mmezi maka akụrụngwa ọrụ ogologo oge (dịka ọmụmaatụ, sistemụ HVAC).

- Nguzogide Mkpọtụ na Nrụgide Njehie: Ike nrụgide ntụgharị ≥460 MPa na-eme ka nkwụsi ike nke usoro kwụsiri ike n'okpuru ịma jijiji (dakọtara na ule ịma jijiji nke IEC 60068-2-6); ntinye zinc nhọrọ na-enye nguzogide ịgba nnu awa 96 (ASTM B117) maka gburugburu ebe mmiri dị ma ọ bụ nke na-emebi emebi (dịka ọmụmaatụ, akụrụngwa mmiri).

- Nhazi nha na-agbanwe agbanwe: Dị na ọkpụrụkpụ nkịtị (0.15mm–0.8mm) na obosara (10mm–200mm) yana ndidi ≤±0.005mm (ọkpụrụkpụ) na ≤±0.1mm (obosara) - na-eme ka stampụ akpaka na njikọta n'ime ihe ndị a na-emepụta n'ụlọ ọrụ mmepụta ihe.

Nkọwapụta Nkà na ụzụ

| Njirimara | Uru (Nkịtị) |

|---|---|

| Oke ọkpụrụkpụ | 0.15mm – 0.8mm (omenala ruo 1.2mm) |

| Oke Obosara | 10mm – 200mm (obosara ọkọlọtọ: 15mm, 20mm, 27mm) |

| Ogologo kwa mpịakọta | 50m – 300m (ogologo dị: ≥100mm) |

| Oke Mgbasawanye Okpomọkụ (Akwa Elu/Akwa Ala) | ~4:1 |

| Oke okpomọkụ ọrụ | -50℃ ruo 250℃ (na-aga n'ihu); Oge dị mkpirikpi: ruo 300℃ (≤1 awa) |

| Mgbanwe Okpomọkụ Mmegharị | ±2℃ (n'ebe a na-eme ihe ngosi, 80℃–200℃) |

| Ike Ịkpụcha Ihu | ≥140 MPa |

| Ike nrụgide (Transverse) | ≥460 MPa |

| Ogologo (25℃) | ≥14% |

| Nguzogide (25℃) | 0.20 – 0.35 Ω·mm²/m |

| Ọdịdị siri ike nke elu (Ra) | ≤0.8μm (ihe eji arụ ọrụ igwe); ≤0.4μm (ihe eji arụ ọrụ nke ọma, nhọrọ) |

Nkọwapụta Ngwaahịa

| ihe | Nkọwapụta |

|---|---|

| Mmecha Elu | Ihe eji arụ ọrụ igwe (enweghị oxide) ma ọ bụ nke a kpụrụ akpụ/nke a kpụrụ akpụ/nke a kpụrụ akpụ (maka mma iguzogide nchara) |

| Ịdị larịị | ≤0.1mm/m (dị oke mkpa maka mgbanwe okpomọkụ otu na izi ezi nke stampụ) |

| Nhazi ọrụ | Dakọtara na CNC stampụ, ịkpụ laser, na ịgbagọ; enweghị mgbawa ihu n'etiti oge nhazi (opekempe mgbagọ radius ≥3 × ọkpụrụkpụ) |

| Ọdịdị Njikọta | Njikọ ihu 100% (enweghị oghere dị n'etiti 0.1mm², nke a kwadoro site na nyocha X-ray na ule ultrasound) |

| Nkwakọ ngwaahịa | A na-eji akpa foil aluminom nke na-anaghị ekpo mmiri mechie ya, nke nwere ihe na-eme ka mmiri ghara ịpụ apụ; ihe e ji osisi rụọ (maka mpịakọta) ma ọ bụ katọn ndị na-anaghị agbagọ agbagọ (maka mpempe akwụkwọ e bepụrụ agbugọ) iji gbochie mmebi. |

| Nhazi | Mgbanwe nke okpomọkụ ime ihe (60℃–220℃), mkpuchi elu, ọdịdị e ji akara mee (kwa faịlụ CAD nke onye ahịa), na ọkpụrụkpụ/obosara na-abụghị ọkọlọtọ |

Ngwa Ndị A Na-ahụkarị

- Njikwa Okpomọkụ Ụlọ Ọrụ: Thermostats maka oven ụlọ ọrụ mmepụta ihe, ihe na-agba mmiri, na sistemu HVAC; ihe na-achịkwa okpomọkụ maka igwe ịkpụzi plastik (na-arụ ọrụ na 120℃–200℃).

- Nchedo Okpomọkụ Oke: Ihe mgbawa sekit okpomọkụ maka moto eletriki (dịka ọmụmaatụ, pọmpụ ụlọ ọrụ mmepụta ihe, compressors) na transformers ike—na-egbochi ike ọgwụgwụ site na ịkwụsị sekit na 150℃–250℃.

- Ụgbọala na Mmiri: Ihe mmetụta okpomọkụ na ihe nchebe maka akụkụ injin (ụgbọala) na akụrụngwa mmiri (na-eguzogide mkpọtụ na ire ere mmiri nnu).

- Ngwaọrụ Nkịtị: Ihe ndị na-eme ka okpomọkụ dị mma maka ihe nlele nrụgide, mita mmiri, na ihe mmetụta MEMS—na-agbanwe njehie mgbasa okpomọkụ iji nọgide na-enwe izi ezi nke nha.

- Ngwa Ezinụlọ na Azụmahịa: Ihe nchebe okpomọkụ gabigara ókè maka ihe na-ekpo ọkụ mmiri eletrik, ihe na-eme ka ikuku dị jụụ, na friji azụmahịa (arụmọrụ kwụsiri ike na gburugburu ebe iru mmiri dị elu).

Tankii Alloy Material na-eji njikwa mma siri ike eme ihe maka TTБ2013/TM-2/108SP bimetallic strips: otu ọ bụla na-eme nnwale shear interfacial, nnwale thermal stability cycle 1000, nyocha nha (laser micrometry), na nhazi okpomọkụ actuation. Ihe nlele efu (100mm × 20mm) na akụkọ arụmọrụ zuru ezu (gụnyere thermal curvature vs. thermal curves) dị ma ọ bụrụ na a rịọ ya. Ndị otu teknụzụ anyị na-enye nkwado ahaziri ahazi - dị ka nhazi oyi akwa alloy maka okpomọkụ ọrụ akọwapụtara na nduzi ndakọrịta na usoro mgbakọ ụlọ ọrụ - iji hụ na stripe ahụ na-emezu mkpa kpọmkwem nke ngwa ụlọ ọrụ Eurasia na ụwa niile.

Dee ozi gị ebe a zitere anyị ya

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu