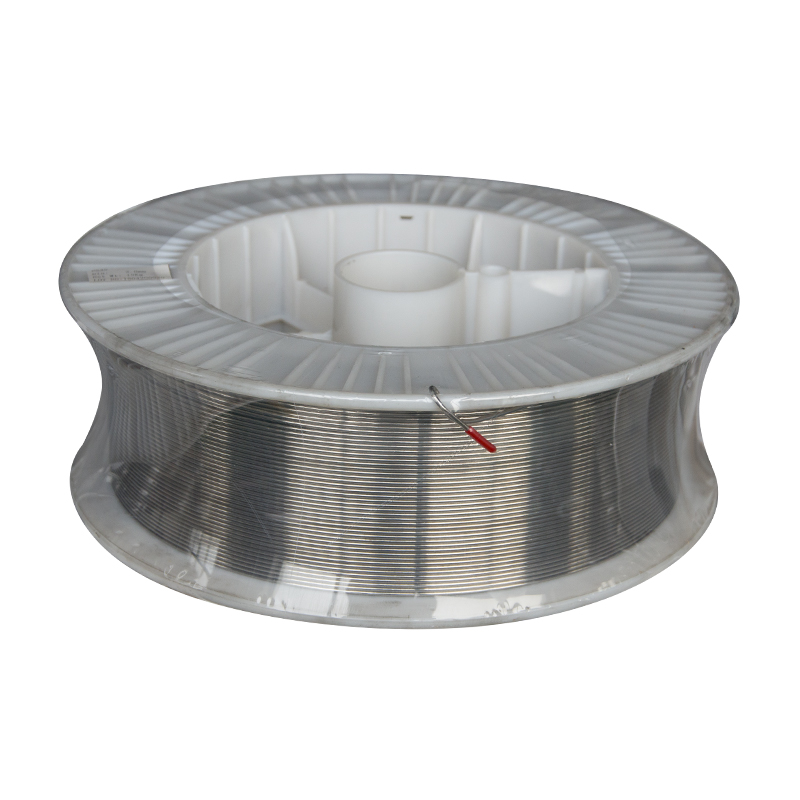

Hastelloy C276 /N10276/NiMo16Cr15W Waya Alloy Okpomọkụ Dị Elu

- Hastelloy C276 Okpomọkụ dị elu nke Alloy Waya Nickel Alloy Waya Hastelloy Coil 760MPA Ike nrụgide

Waya Hastelloy C22 bụ waya alloy dabere na nickel nke nwere arụmọrụ dị elu, nke nwere ezigbo iguzogide nchara na oke okpomọkụ. A na-ejikarị ya eme ihe n'ọhịa ụlọ ọrụ n'okpuru gburugburu ebe dị oke njọ. Ihe ndị bụ isi ya gụnyere nickel, chromium, molybdenum na tungsten. Ọ nwere ike ịrụ ọrụ nke ọma n'ibelata na ibelata mgbasa ozi, ọkachasị pitting, crevice corrosion na stress corrosion crashing nke chlorides kpatara. Alloy ahụ nwere ike ịdọkpụ nke 690-1000 MPa, ike mmepụta nke 283-600 MPa, ogologo nke 30%-50%, njupụta nke 8.89-8.95 g/cm³, ike okpomọkụ nke 12.1-15.1 W/(m·℃), na oke mgbasa nke (10.5-13.5) × 10⁻⁶/℃. Waya Hastelloy C22 ka nwere ike ịnọgide na-enwe ezigbo ihe onwunwe igwe na iguzogide oxidation na okpomọkụ dị elu ma enwere ike iji ya na gburugburu ruo 1000℃. Ọ nwere ezigbo arụmọrụ nhazi ma dabara adaba maka usoro dịka ịtụgharị oyi, mkpụpụ oyi, na ịgbado ọkụ, mana o nwere ike ịrụsi ọrụ ike ma nwee ike ịchọ annealing. A na-eji waya Hastelloy C22 eme ihe nke ukwuu na ụlọ ọrụ kemịkalụ, mmiri, nuklia, ike na ọgwụ iji mepụta reactors, ihe mgbanwe okpomọkụ, paịpụ, valvụ na akụrụngwa mmiri.

-

Njirimara Kemịkalụ nke Hastelloy C276

;

| Hastelloy Alloy | Ni | Cr | Co | Mo | FE | W | Mn | C | V | P | S | Si |

| C276 | Nhazi nguzozi | 20.5-22.5 | Oke kachasị elu 2.5 | 12.5-14.5 | 2.0-6.0 | 2.5-3.5 | 1.0 Kachasị | Oke kachasị 0.015 | 0.35 Kachasị | 0.04 Kachasị | 0.02 Kachasị | Oke kachasị 0.08 |

- ;Ngwa

Ụlọ ọrụ Kemịkal: Ọ dabara adaba maka akụrụngwa ndị a na-ekpughere na asịd siri ike, alkalis siri ike na ihe ndị na-eme ka oxidant dị ike, dị ka reaktọ, pipelines na valvụ.

Mmanụ na Gas: A na-ejikarị ya eme ihe n'ọtụtụ ebe na paịpụ mmanụ, ngwa nrụzi na paịpụ mmiri n'okpuru mmiri n'ihi ezigbo iguzogide nchara hydrogen sulfide.

Aerospace: A na-eji ya emepụta mgbanaka mkpuchi gas turbine, ihe njide siri ike, wdg.

Injinịa Mmiri: N'ihi na ọ naghị eguzogide nchara mmiri, a na-ejikarị ya eme ihe na sistemụ oyi mmiri.

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu