Nnọọ na weebụsaịtị anyị!

FeCrAl FeCr23Al5 A1 APM AF D Waya eletriki na-eguzogide okpomọkụ nke alloy

FeCrAl A1 APM AF D Waya eletriki na-eguzogide okpomọkụ nke alloy

Banyere Waya Nguzogide Ọkụ:

Anyị bụ ndị ọkachamara kachasị na-emepụta ihe mkpuchi okpomọkụ na China, anyị na-arụ ọrụ na waya Ferro-Chrome (Fe-Cr-AL), waya Nickel-Chrome (Nichrome), waya Copper Nickel (Constantan), waya ígwè anaghị agba nchara na ngwaahịa ndị metụtara ya na alloys nke ahaziri iji mezuo ihe ndị ahịa chọrọ.

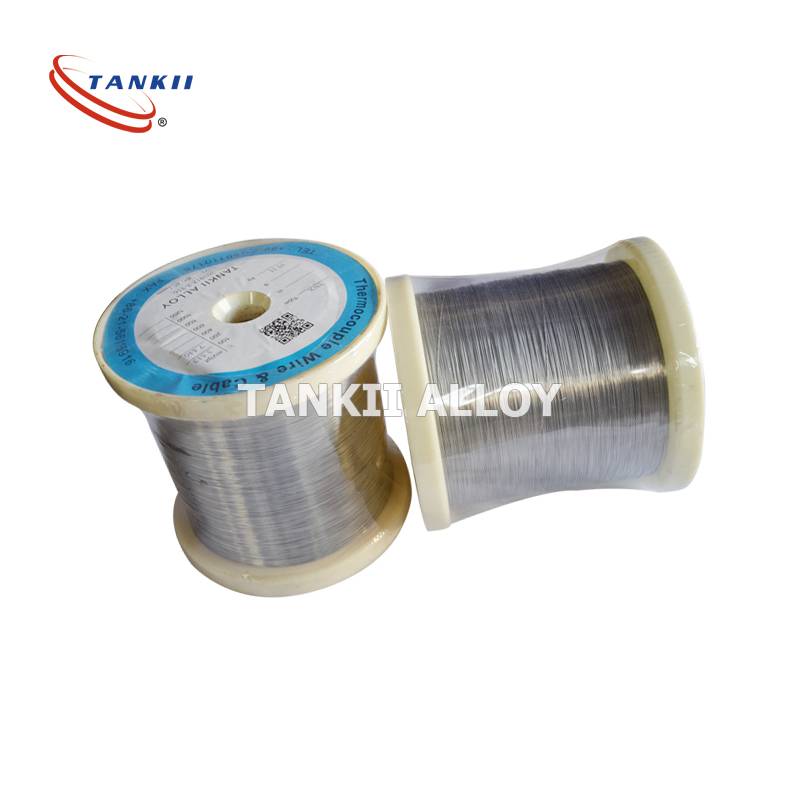

Nkọwa nha

| Aha ngwaahịa | Oke nha |

| Waya ịbịaru oyi | Dayameta 0.03-7.5mm |

| Mkpanaka waya a na-akpọgharị ọkụ | Dayameta 8.0-12mm |

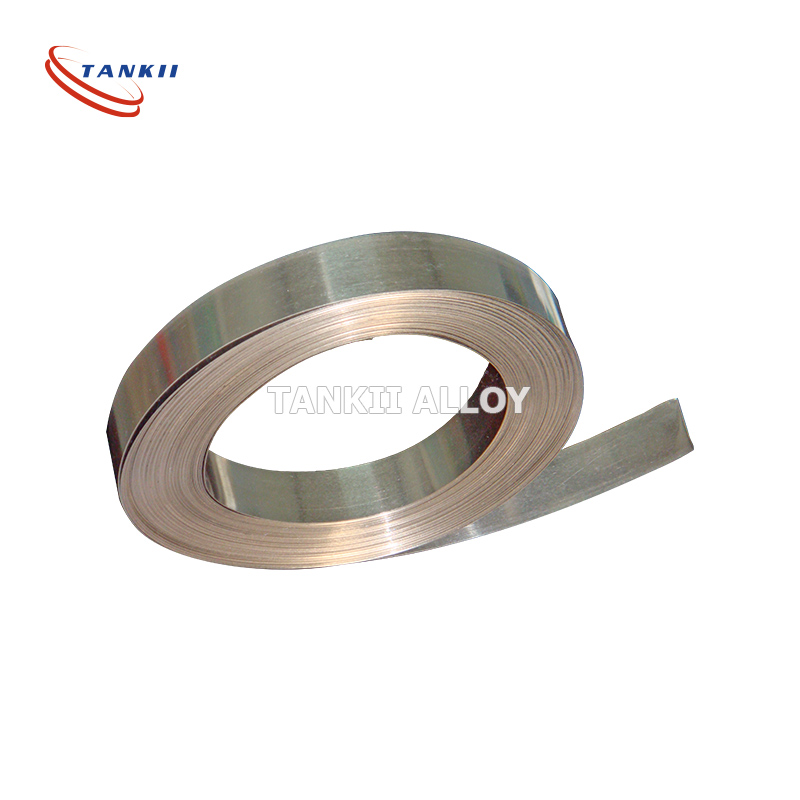

| Ribọn | Ọkpụrụkpụ 0.05-0.35mm |

| Obosara 0.5.0-3.5mm | |

| Mpempe akwụkwọ oyi a kpụkọrọ akpụkọ | Ọkpụrụkpụ 0.5-2.5mm |

| Obosara 5.0-40mm | |

| eriri a na-akpọgharị ọkụ | Ọkpụrụkpụ 4-6mm |

| Obosara 15-40mm |

paramita ndị bụ isi:

| paramita ndị bụ isi | APMTM | FeCrAl | ||

| A-1 | AF | D | ||

| Okpomọkụ ọrụ kachasị elu | 1425 | 1400 | 1300 | 1300 |

| Ihe mejupụtara kemịkalụ aha,% Cr | 22 | 22 | 22 | 22 |

| AI | 5.8 | 5.8 | 5.3 | 4.8 |

| Fe | ihe ndị e ji mee ihe | ihe ndị e ji mee ihe | ihe ndị e ji mee ihe | ihe ndị e ji mee ihe |

| Ni | - | - | - | - |

| Nguzogide na 20ºC, Ωmm-2mm-1 | 1.45 | 1.45 | 1.39 | 1.35 |

| njupụta, g/cm3 | 7.1 | 7.1 | 7.15 | 7.25 |

| Oke mgbasa okpomọkụ K-1 20-750ºC | 14 × 10-6 | 14 × 10-6 | 14 × 10-6 | 14 × 10-6 |

| 20-1000ºC | 15 × 10-6 | 15 × 10-6 | 15 × 10-6 | 15 × 10-6 |

| Ọkwa okpomọkụ 20ºC, Wm-1K-1 | 13 | 13 | 13 | 13 |

| Ike okpomọkụ kpọmkwem 20ºC,KJkg-1K-1 | 0.46 | 0.46 | 0.46 | 0.46 |

| Isi agbaze°C | 1500 | 1500 | 1500 | 1500 |

| Ikekwe njirimara igwe | ||||

| Ike nrụgide, N mm-2 | 680 | 680 | 680 | 650 |

| Ike mmepụta, N mm-2 | 470 | 475 | 475 | 450 |

| Ike, Hv | 230 | 230 | 230 | 230 |

| Ogologo oge na-agbawa agbawa,% | 20 | 18 | 18 | 18 |

| Ike nrụgide 900ºCT, N mm-2 | 40 | 34 | 37 | 34 |

| Ike ịkpa ike 800ºC | 11 | 6 | 8 | 6 |

| 1000ºC | 3.4 | 1 | 1.5 | 1 |

| Magnetik | magnetik (Na okpomọkụ 600ºC) | |||

| Mmiri na-ekpo ọkụ, ọnọdụ oxidation | 0.7 | 0.7 | 0.7 | 0.7 |

Nkọwapụta:

| Ụdị Alloy | Dayameta | Nguzogide | Ndọkpụ | Ogologo oge (%) | Ịgbagọ | Kasị elu | Ndụ Ịrụ Ọrụ |

| (mm) | (μΩm)(20°C) | Ike | Oge | Ọrụ | (awa) | ||

| (N/mm²) | Okpomọkụ (°C) | ||||||

| Cr20Ni80 | <0.50 | 1.09±0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14±0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18±0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20±0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12±0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15±0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04±0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06±0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25±0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25±0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35±0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42±0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23±0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45±0.07 | 634-784 | >12 | >5 | 1350 | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

Uru:

Nickelchromium alloy nwere oke iguzogide siri ike, iguzogide corrosion, iguzogide oxidation elu dị mma, ka mma n'okpuru oke okpomọkụ na ike ala ọma jijiji, ezigbo ductility, ezigbo ọrụ na weldability.

Dee ozi gị ebe a zitere anyị ya

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu