Nnọọ na weebụsaịtị anyị!

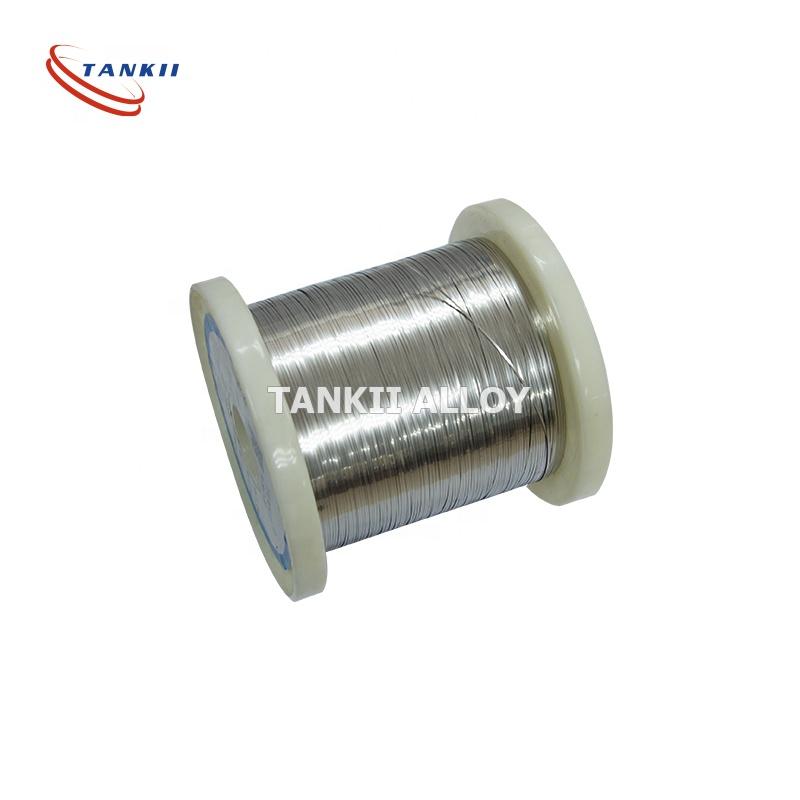

FeCrAl 0cr23al5 waya dị larịị na eriri ọkụ site na ụlọ ọrụ mmepụta ihe

FeCrAl 0cr23al5 waya dị larịị & ihe na-ekpo ọkụwararasite na ụlọ ọrụ mmepụta ihe

| Ọkwa | 0Cr23Al5 |

| Nha | ọkpụrụkpụ:0.05-3mm obosara: 4-250mm |

| Elu | nchacha na-egbuke egbuke |

| Ibu | 1-3kg/mpịakọta, dịka ọnụọgụ ndị ahịa si dị |

| Nguzogide | 1.3±0.05μΩ.m |

| Ike siri ike (HV) | 180-210HV |

| Ogologo | ≥16% |

| Ọkwa | Okpomọkụ kachasị elu | Nguzogide | Ike siri ike | Ike ọdụdọ | Ogologo |

| 0Cr13Al4 | 1050℃ | 1.25±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1.42±0.05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr25Ni20(310S) | 1100℃ | 0.86±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Ọkwa | Ihe mejupụtara kemịkalụ% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | nguzozi |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | nguzozi |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | nguzozi |

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | nguzozi | <0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | <0.5 | nguzozi |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | nguzozi |

| Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | nguzozi |

Shanghai Tankii Alloy Material Co.,Ltd. na-elekwasị anya na mmepụta nke nichrome alloy, thermocouple waya, fecral alloy,precision alloy,copper nickel alloy,thermal spray alloy wdg. n'ụdị waya,mpempe akwụkwọ,tepe,warara,mkpara na efere.

Anyị enwetala asambodo sistemụ mma ISO 9001 na nkwenye nke sistemụ nchekwa gburugburu ebe obibi ISO 14001. Anyị nwere usoro mmepụta zuru oke nke nchacha, mbelata oyi, eserese na ọgwụgwọ okpomọkụ wdg. Anyị jikwa nganga nwee ikike nyocha na nhazi onwe anyị.

Dee ozi gị ebe a zitere anyị ya

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu