Ihe mkpuchi PTFE siri ike N Thermocouple Alloy

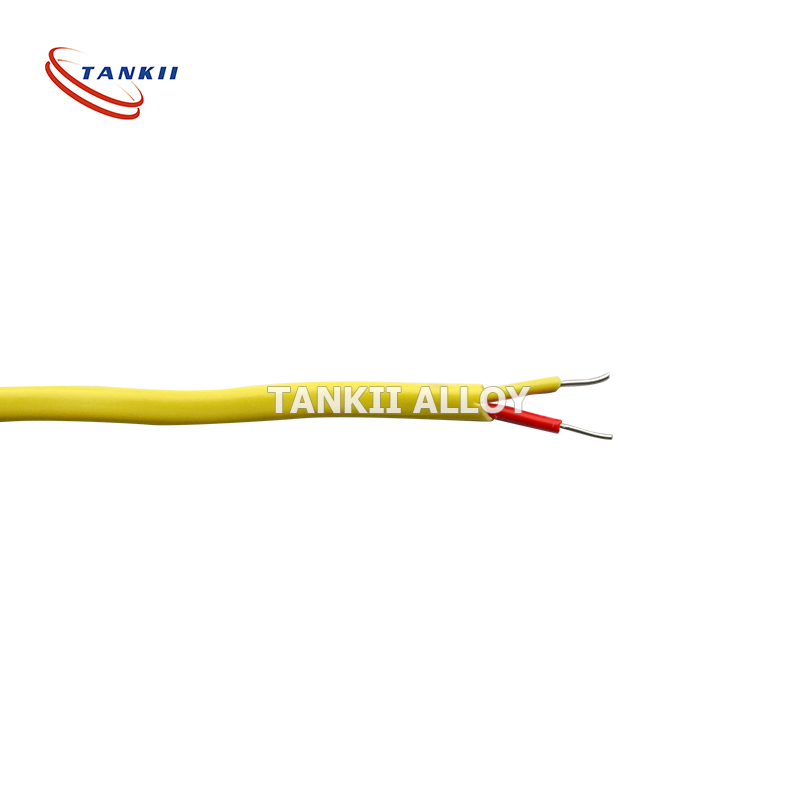

Nkọwapụta

1. Ụdị: Waya Mgbatị

2.Thermocouplewaya ọla kọpa

Nkewa waya ọla kọpa Thermocouple

1. Ọkwa Thermocouple (ọkwa okpomọkụ dị elu). Ụdị waya thermocouple a dabara adaba maka ụdị thermocouple K, J, E, T, N na L yana ngwa nchọpụta okpomọkụ dị elu, ihe mmetụta okpomọkụ, wdg.

2. Ọkwa waya na-akwụghachi ụgwọ (ọkwa okpomọkụ dị ala). Ụdị waya thermocouple a dabara adaba maka eriri na waya ndọtị nke ụdị thermocouples dị iche iche dịka S, R, B, K, E, J, T, N na L, eriri ọkụ, eriri njikwa na ihe ndị ọzọ.

Ụdị na ndeksi nke Thermocouple

| Ụdị na Ndepụta nke Thermocouple | ||

| Ụdị dị iche iche | Ụdị | Oke nha (°C) |

| NiCr-NiSi | K | -200-1300 |

| NiCr-CuNi | E | -200-900 |

| Fe-CuNi | J | -40-750 |

| Cu-CuNi | T | -200-350 |

| NiCrSi-NiSi | N | -200-1300 |

| NiCr-AuFe0.07 | NiCr-AuFe0.07 | -270-0 |

Akụkụ na Ntachi Obi nke Waya Thermocouple Fiberglass Insulated

Nha / Ntachi obi mm): 4.0+-0.25

Koodu agba na nnabata nhazi mbụ maka waya thermocouple:

| Ụdị Thermocouple | Koodu Agba ANSI | Nkwenye Nhazi Mbụ | ||||

| Alloys waya | Nhazi | +/- Onye na-eduzi ihe | Jaketị | Oke okpomọkụ | Ọkọlọtọ Oke | Pụrụ Iche Oke |

| Ígwè(+) vs. Kọnstantan(-) | J | Ọcha/Uhie | Agba aja aja | 0°C ruo +285°C 285°C ruo +750°C | ±2.2°C ±.75% | ±1.1°C ±.4% |

| CHROMEL(+) vs. ALUMEL(-) | K | Odo/Uhie | Agba aja aja | -200°C ruo -110°C -110°C ruo 0°C 0°C ruo +285°C 285°C ruo +1250°C | ± 2% ±2.2°C ±2.2°C ±.75% | ±1.1°C ±.4% |

| Kọpa(+) vs. Kọnstantan(-) | T | Anụ anụnụ/Uhie | Agba aja aja | -200°C ruo -65°C -65°C ruo +130°C 130°C ruo +350°C | ± 1.5% ±1°C ±.75% | ±.8% ± .5°C ±.4% |

| CHROMEL(+) vs. Kọnstantan(-) | E | Ọcha/Uhie | Agba aja aja | -200°C ruo -170°C -170°C ruo +250°C 250°C ruo +340°C 340°C+900°C | ± 1% ±1.7°C ±1.7°C ±.5% | ±1°C ±1°C ±.4% ±.4% |

Koodu Agba na Nkwenye Nhazi Mbụ maka Waya Mgbatị:

| Ụdị ndọtị | Koodu Agba ANSI | Nkwenye Nhazi Mbụ | ||||

| Alloys waya | Nhazi | +/- Onye na-eduzi ihe | Jaketị | Oke okpomọkụ | Ọkọlọtọ Oke | Pụrụ Iche Oke |

| Ígwè (+) vs. Constantan (-) | JX | Ọcha/Uhie | Ojii | 0°C ruo +200°C | ±2.2°C | ±1.1°C |

| CHROMEL (+) megide ALUMEL (-) | KX | Odo/Uhie | Odo odo | 0°C ruo +200°C | ±2.2°C | ±1.1°C |

| Kọpa(+) vs. Constantan(-) | TX | Anụ anụnụ/Uhie | Anụ anụnụ anụnụ | -60°C ruo +100°C | ±1.1°C | ± .5°C |

| CHROMEL(+) megide Constantan(-) | EX | Ọcha/Uhie | Agba odo odo | 0°C ruo +200°C | ±1.7°C | ±1.1°C |

Njirimara anụ ahụ nke PVC-PVC:

| Àgwà | Mkpuchi | Jaketị |

| Nguzogide Abrasion | Ọ dị mma | Ọ dị mma |

| Nguzogide Belata | Ọ dị mma | Ọ dị mma |

| Mgbochi Mmiri | Ọ dị mma nke ukwuu | Ọ dị mma nke ukwuu |

| Nguzogide ígwè na-agba ígwè | Ogbenye | Ogbenye |

| Okpomọkụ Ọrụ | 105ºC na-aga n'ihu 150ºC otu | 105ºC na-aga n'ihu 150ºC otu |

| Ule ire ọkụ | Na-emenyụ onwe ya | Na-emenyụ onwe ya |

Nkọwapụta Ụlọ ọrụ

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu