815 MPA lncoloy 925 UNS N09925 eriri corrosion Alloy

815 MPA lncoloy 925 UNS N09925 mpempe nchara Nkọwa nke Alloy:

Incoloy alloy 925 (UNS N09925) Site na mgbakwunye nke molybdenum, ọla kọpa, titanium, na aluminom bụ ihe mgbakwunye nickel-iron-chromium nke a na-eme ka ọ sie ike ruo ogologo oge, na-enye njikọta nke ike dị elu na ezigbo iguzogide nchara. Ngụkọta nickel zuru oke na-enye nchebe megide mgbawa nrụgide chloride-ion-corrosion ebe ọ bụ na conjuncton na molybdenum na ọla kọpa agbakwunyere, a na-enweta iguzogide kemịkalụ na-ebelata. Molybdenum na-enyekwa aka na iguzogide pitting na corrosion crevice, ebe chromium na-enye iguzogide gburugburu oxidizing. N'oge ọgwụgwọ okpomọkụ, mmeghachi omume na-eme ka ọ sie ike site na mgbakwunye nke titanium na aluminom.

Ngwa ndị chọrọ njikọta nke ike dị elu na iguzogide nchara nwere ike ịtụle alloy Incoloy 925. Nguzogide nke mgbawa nrụgide sulfide na mgbawa nrụgide-njehie na gburugburu mmanụ ala na gas eke pụtara na ejiri ya maka akụkụ olulu gas dị n'okpuru ala na n'elu yana ịchọta ojiji na ogwe mmiri na ọkpọ mmiri ma ọ bụ sistemụ ọkpọkọ siri ike.

-

1. Ihe achọrọ maka nhazi kemịkalụ

Ihe mejupụtara kemịkalụ nke Incoloy 925 Nickel 42.0-46.0 Chromium 19.5-22.5 Ígwè ≥22.0 Molybdenum 2.5-3.5 Ọla kọpa 1.5-3.0 Titanium 1.9-2.4 Aluminium 0.1-0.5 Manganese ≤1.00 Silikọn ≤0.50 Niobium ≤0.50 Kabọn ≤0.03 Sọlfọ ≤0.30

-

2. Njirimara Mekaniki nke Incoloy 925

Ike nrụgide, nkeji. Ike Mwepụta, nkeji. Ogologo, nkeji. Isi ike, nkeji. Mpa ksi Mpa ksi % HRC 1210 176 815 118 24 36.5 3. Njirimara anụ ahụ nke Incoloy 925

Njupụta Oke agbaze Okpomọkụ Pụrụ Iche Nguzogide Ọdụdọ Eletriki g/cm3 °F °C J/kg.k Btu/lb. °F µΩ·m 8.08 2392-2490 1311-1366 435 0.104 1166 4. Ụdị na Ụkpụrụ Ngwaahịa

Fọm Ngwaahịa Ọkọlọtọ Mkpanaka, mmanya na waya ASTM B805 Efere, mpempe akwụkwọ nawarara ASTM B872 Pipe na tube na-enweghị ntụpọ ASTM B983 Ịkpụpụta ASTM B637

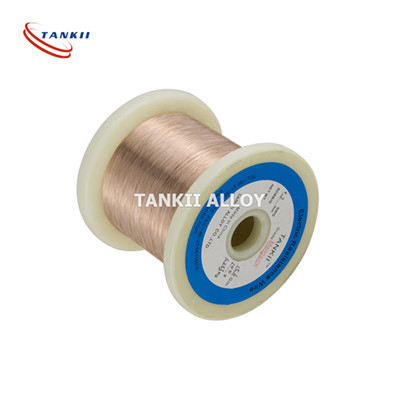

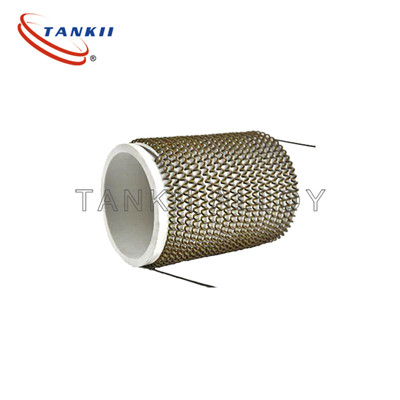

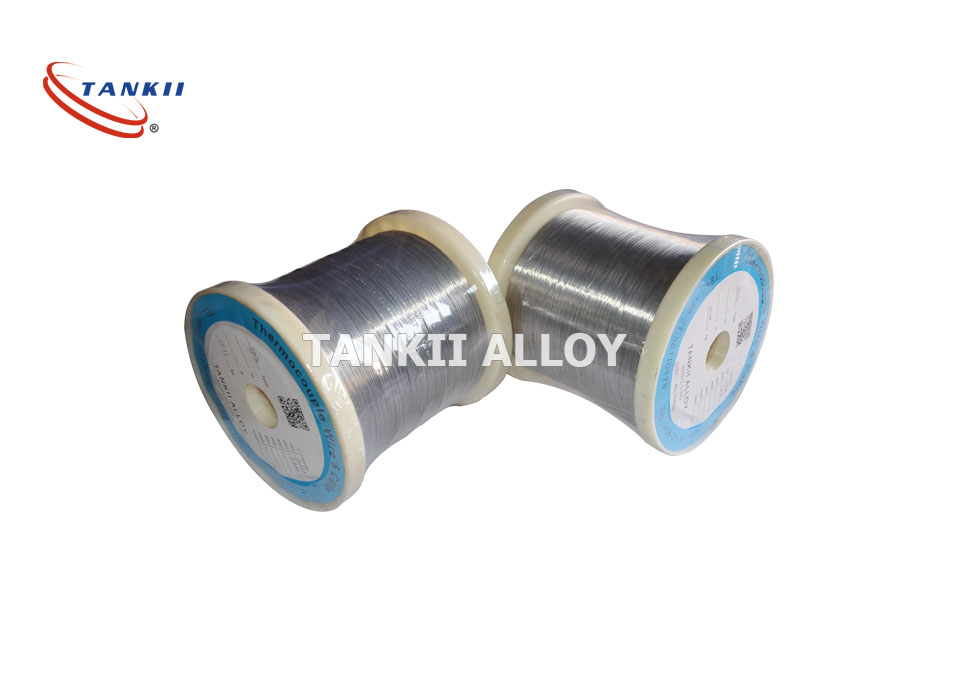

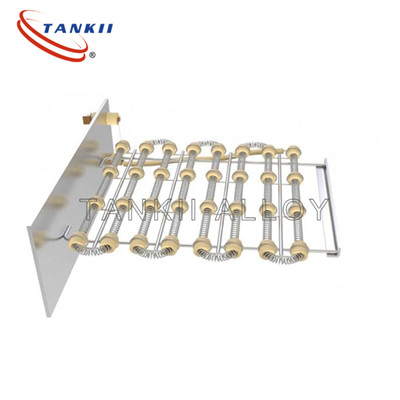

Foto nkọwa ngwaahịa:

Nduzi Ngwaahịa Ndị Yiri Ya:

Anyị nwere ezigbo ọnọdụ n'etiti ndị na-atụ anya ngwaahịa anyị dị elu, ọnụ ahịa asọmpi na ọrụ kacha mma maka 815 MPA lncoloy 925 UNS N09925 corrosion strip Alloy, Ngwaahịa a ga-enye ụwa niile, dịka: Philadelphia, Nicaragua, Yemen, Iji nweta uru ndị ọzọ, ụlọ ọrụ anyị na-akwalite usoro anyị nke ijikọ ụwa ọnụ n'ihe gbasara nkwukọrịta na ndị ahịa si mba ofesi, nnyefe ngwa ngwa, ịdị mma kacha mma na mmekorita ogologo oge. Ụlọ ọrụ anyị na-akwado mmụọ nke "ihe ọhụrụ, nkwekọrịta, ọrụ otu na ịkekọrịta, ụzọ, ọganihu bara uru". Nye anyị ohere anyị ga-egosipụta ikike anyị. Site n'enyemaka obiọma gị, anyị kwenyere na anyị nwere ike ịmepụta ọdịnihu na-egbuke egbuke na gị ọnụ.

Ọ dịghị mfe ịchọta onye ọrụ ọkachamara na onye nwere ọrụ dị otú a n'oge a. Enwere m olileanya na anyị ga-enwe ike ịnọgide na-enwe mmekorita ogologo oge.

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu