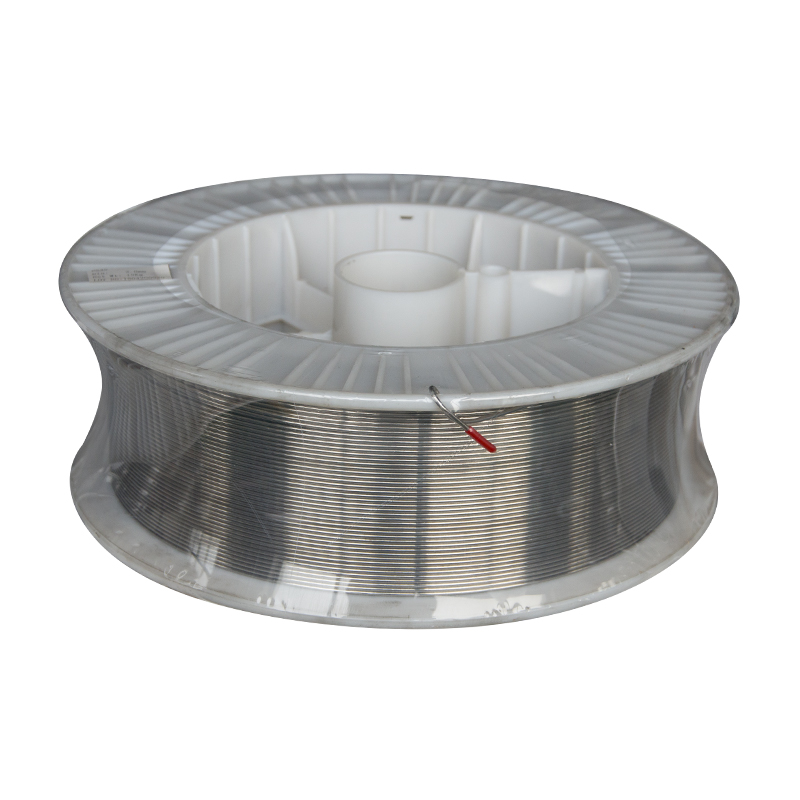

Waya Invar Alloy 4j36 Low Mgbasawanye Alloy Feni36

4J36 (Invar) a na-eji ya ebe achọrọ nkwụsi ike dị elu, dịka ngwa ọrụ nkenke, elekere, ihe nlele seismic creep, fremu ihe mkpuchi ihu telivishọn, valvụ na moto, na elekere antimagnetic. N'ịnyocha ala, mgbe a ga-eme nhazi elu nke mbụ (nke ziri ezi), a na-eji Invar eme mkpara Level (mkpanaka ọkwa) eji eme ihe, kama osisi, fiberglass, ma ọ bụ ọla ndị ọzọ. E jiri Invar struts mee ụfọdụ piston iji belata mgbasawanye okpomọkụ ha n'ime silinda ha.

4J36 jiri oxyacetylene ịgbado ọkụ, ịgbado ọkụ eletrik, ịgbado ọkụ na ụzọ ịgbado ọkụ ndị ọzọ. Ebe ọ bụ na e kwesịrị izere oke mgbasa na nhazi kemịkalụ nke alloy ahụ n'ihi na ịgbado ọkụ na-akpata mgbanwe na nhazi alloy ahụ, ọ ka mma iji ígwè ndị na-ejupụta ihe mkpuchi Argon arc nke nwere titanium 0.5% ruo 1.5%, iji belata porosity na mgbawa nke ịgbado ọkụ.

Ihe mejupụtara nkịtị%

| Ni | 35~37.0 | Fe | Bọl. | Co | - | Si | ≤0.3 |

| Mo | - | Cu | - | Cr | - | Mn | 0.2~0.6 |

| C | ≤0.05 | P | ≤0.02 | S | ≤0.02 |

Ọnụọgụ nke mgbasawanye

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20~-60 | 1.8 | 20-250 | 3.6 |

| 20~-40 | 1.8 | 20-300 | 5.2 |

| 20~-20 | 1.6 | 20-350 | 6.5 |

| 20~-0 | 1.6 | 20-400 | 7.8 |

| 20-50 | 1.1 | 20-450 | 8.9 |

| 20~100 | 1.4 | 20-500 | 9.7 |

| 20~150 | 1.9 | 20~550 | 10.4 |

| 20-200 | 2.5 | 20-600 | 11.0 |

Àgwà anụ ahụ nkịtị

| Njupụta (g/cm3) | 8.1 |

| Nguzogide eletriki na 20ºC (OMmm2/m) | 0.78 |

| Ọnọdụ okpomọkụ nke resistivity (20ºC ~ 200ºC) X10-6/ºC | 3.7~3.9 |

| Ọgbakọ okpomọkụ, λ/ W/(m*ºC) | 11 |

| Isi Curie Tc/ºC | 230 |

| Elastic Modulus, E/ Gpa | 144 |

| Usoro ọgwụgwọ okpomọkụ | |

| Ịkwụsị nrụgide maka iwepụ nrụgide | A na-ekpo ọkụ ruo 530 ~ 550ºC ma jide ruo awa 1-2. Oyi gbazee |

| ịkụcha ihe | Iji wepụ ike siri ike, nke a ga-ewepụta n'usoro ise ihe oyi na-akpọchi akpọchi. A ghaghị ikpo ọkụ na-ekpo ọkụ ruo 830 ~ 880ºC n'ime oghere ikuku, jide nkeji iri atọ. |

| Usoro nkwụsi ike |

|

| Mkpachapụ anya |

|

Njirimara Mechanical nkịtị

| Ike ọdụdọ | Ogologo |

| Mpa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Ihe na-akpata okpomọkụ nke iguzogide

| Oke okpomọkụ, ºC | 20-50 | 20~100 | 20-200 | 20-300 | 20-400 |

| aR/ 103 *ºC | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu