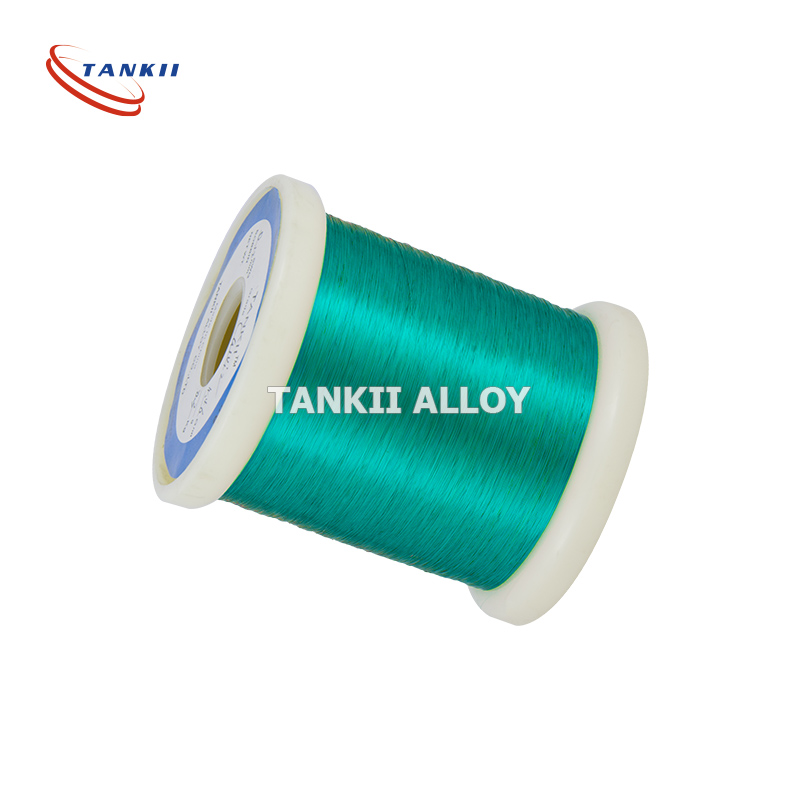

0.2mm 130 Klas Enameled Waya Agba Agba nke Alloy Copper Alloy Manganin

Waya enamel agba gburugburu nke ọla kọpa 130

1. Nkọwa Izugbe Ihe

Aluminom ọla kọpa, nke nwere obere iguzogide ọkụ eletrik, ezigbo iguzogide okpomọkụ na iguzogide nchara, ọ dị mfe nhazi na ịgbado ọkụ lead. A na-eji ya eme ihe ndị bụ isi na relay okpomọkụ, obere ihe mgbochi okpomọkụ, na ngwa eletriki. Ọ bụkwa ihe dị mkpa maka eriri ọkụ eletrik. Ọ dị ka ụdị cupronickel. Ka Nickel na-eme ka ihe mejupụtara ya dịkwuo mma, otú ahụ ka elu ya na-acha ọcha ọlaọcha.

3. Ihe mejupụtara kemịkalụ na ihe onwunwe bụ isi nke Cu-Ni Low Resistance Alloy

| NjirimaraGrade | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Isi ihe mejupụtara kemịkalụ | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bọọl | Bọọl | Bọọl | Bọọl | Bọọl | Bọọl | |

| Oke Okpomọkụ Ọrụ Na-aga n'ihu (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Ndozi ike na 20oC (Ωmm2/m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Njupụta (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Ọgbakọ okpomọkụ (α×10-6/oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Ike nrụgide (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu(μV/oC)(0~100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Ebe Mgbaze Dị Ihe Dị Ka Ya (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Nhazi Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | |

| Njirimara Magnetik | abụghị | abụghị | abụghị | abụghị | abụghị | abụghị | |

| NjirimaraGrade | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Isi ihe mejupụtara kemịkalụ | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bọọl | Bọọl | Bọọl | Bọọl | Bọọl | Bọọl | |

| Oke Okpomọkụ Ọrụ Na-aga n'ihu (oC) | 300 | 300 | 300 | 350 | 350 | narị anọ | |

| Ndozi ike na 20oC (Ωmm2/m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Njupụta (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Ọgbakọ okpomọkụ (α×10-6/oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Ike nrụgide (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu(μV/oC)(0~100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Ebe Mgbaze Dị Ihe Dị Ka Ya (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Nhazi Micrographic | austenit | austenit | austenit | austenit | austenit | austenit | |

| Njirimara Magnetik | abụghị | abụghị | abụghị | abụghị | abụghị | abụghị | |

2. Okwu Mmalite na ngwa nke Waya Enamel

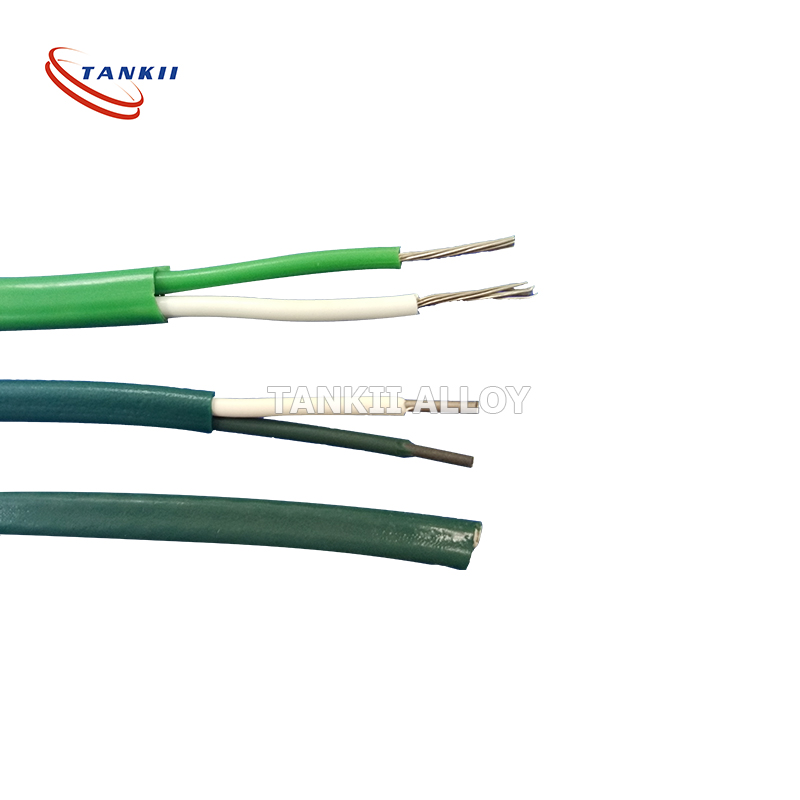

Ọ bụ ezie na a kọwara ya dị ka "enameled", n'eziokwu, waya enamel anaghị ekpuchi ya na agba enamel ma ọ bụ vitreous enamel nke e ji ntụ ntụ iko gwakọtara agwakọta mee. Waya magnet nke oge a na-ejikarị otu ruo anọ (n'ihe gbasara waya ụdị quad-film) nke mkpuchi ihe nkiri polymer, nke na-abụkarị ihe mejupụtara abụọ dị iche iche, iji nye oyi akwa mkpuchi siri ike, na-aga n'ihu. Ihe nkiri mkpuchi waya magnet na-eji (n'usoro okpomọkụ na-abawanye) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyster,polyester-polyimide, polyamide-polyimide (ma ọ bụ amide-imide), na polyimide. Waya magnet nke Polyimide nwere ike ịrụ ọrụ ruo 250 Celsius. A na-ejikarị teepu polyimide ma ọ bụ fiberglass nke nwere oke okpomọkụ kpuchie ya, a na-etinyekwa wiring ndị emechara eme ihe na varnish iji melite ike mkpuchi na ntụkwasị obi ogologo oge nke wiring ahụ.

A na-eji waya kpuchie eriri ndị na-akwado onwe ha ma ọ dịkarịa ala akwa abụọ, nke kachasị mpụta bụ thermoplastic nke na-ejikọta ntụgharị ahụ mgbe a na-ekpo ọkụ.

Ụdị mkpuchi ndị ọzọ dịka eriri fiberglass na varnish, akwụkwọ aramid, akwụkwọ kraft, mica, napolyesterA na-ejikwa ihe nkiri eme ihe n'ọtụtụ ebe n'ụwa niile maka ọtụtụ ọrụ dịka transformers na reactors. N'akụkụ ọdịyo, enwere ike ịchọta waya nke ihe owuwu ọlaọcha, na ọtụtụ ihe mkpuchi ndị ọzọ, dị ka owu (mgbe ụfọdụ a na-ejupụta na ụdị ihe na-eme ka ihe dị arọ/dị arọ, dị ka beeswax) na polytetrafluoroethylene (PTFE). Ihe mkpuchi ochie gụnyere owu, akwụkwọ, ma ọ bụ silk, mana ndị a bara uru naanị maka ojiji dị ala (ruo 105°C).

Maka mfe imepụta ihe, ụfọdụ waya magnet nke nwere obere okpomọkụ nwere ihe mkpuchi nke enwere ike iwepụ site na okpomọkụ nke ihe mkpuchi. Nke a pụtara na enwere ike ịme njikọ eletriki na nsọtụ ya na-ebughị ụzọ wepụ ihe mkpuchi ahụ.

Ngwaahịa dị iche iche

-

Ekwentị

-

Ozi ịntanetị

-

WhatsApp

-

WeChat

Judy

150 0000 2421

-

Elu